Metal Engraving and Marking with Fiber Laser Machines

For almost any metals, fiber laser machines provide readable marks quickly and efficiently. They’re ideal for engraving all types of metal surfaces. Examples include aluminum, anodized aluminum, steel, stainless steel, magnesium, lead, and titanium.

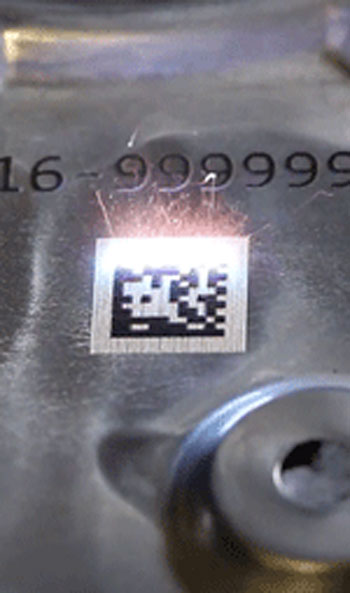

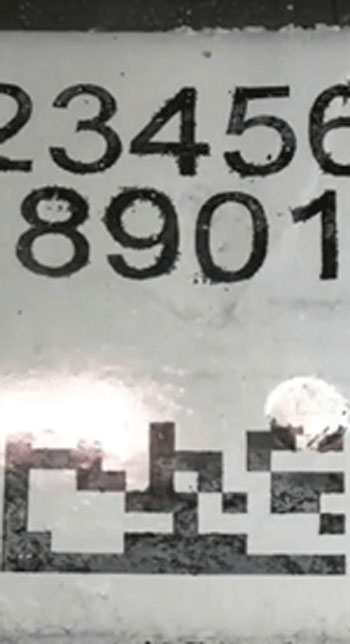

Fiber laser machines are low maintenance, use no consumables, and create high-contrast marks. You can use them to permanently mark data matrix codes, QR codes, serial numbers, barcodes, logos, and more.

Tell us about your application

Trusted by...

Metal Engraving Machines for Production Lines

Machines manufactured by Laserax are turnkey marking solutions ready to be integrated in production lines. Manually loaded or fully automated, they include laser safety, dust extraction, barcode validation, and remote support.

Jump to:

Laser Machines Benefits of Lasers

Aluminum Steel Stainless Steel Anodized Aluminum Magnesium Lead Zinc Other Materials

Laser Etching Laser Engraving Laser Annealing Deep Laser Engraving FAQs

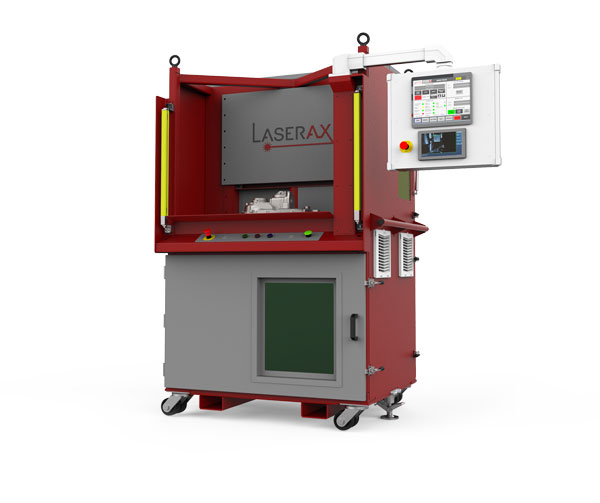

Manually Loaded Laser Marking Machines

-

Flex Workstation

The Flex is our simplest turnkey machine since it includes the least amount of automation, but it can be automated with minimal upgrade any time. It is ideal when a fast marking time isn’t a priority, or when part loading represents a minor portion of the total marking time.

View Machine -

Rotary-Table Workstation

Designed to minimize the impact of part loading on your cycle time, this machine uses a rotary table to allow multiple operations at the same time. The operator can load and unload parts, trigger table rotations, and start laser marking.

View Machine

Fully Automated Laser Marking Machines

-

Rotary-Table Machine

With challenging requirements, the key to prevent bottlenecks is to mark in hidden time. This machine achieves this using a rotary table. While a robot arm loads a part, another part is engraved at the same time.

View Machine -

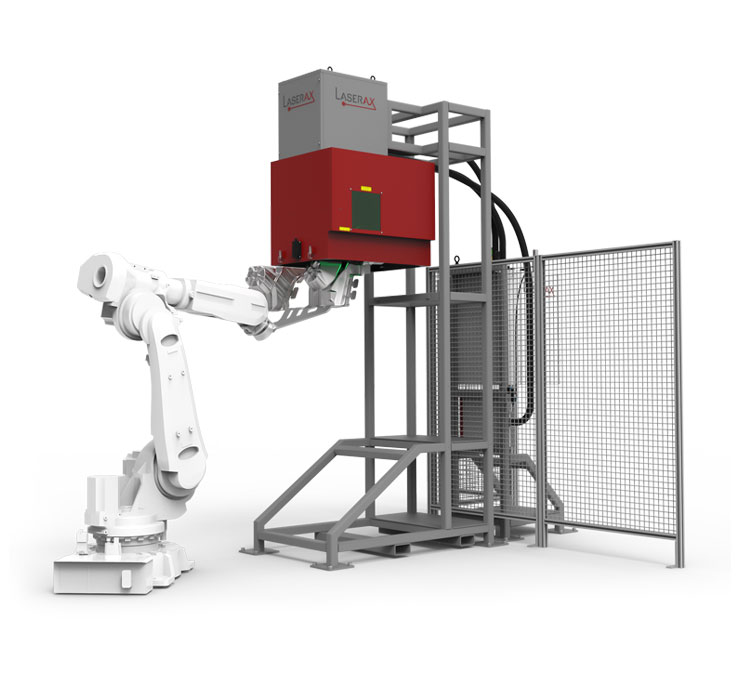

Open-Air Machine

Robots used for multiple operations can be leveraged by opting for an open-air design, where the robot moves parts between stations and hold them during marking. This design easily supports multiple parts and cavities.

View Machine -

Door Machine

With a flexible door machine design, markings can be positioned anywhere, and robot arms can load parts from any direction. These machines are perfect when the robot needs to perform other tasks during the marking operation.

View Machine -

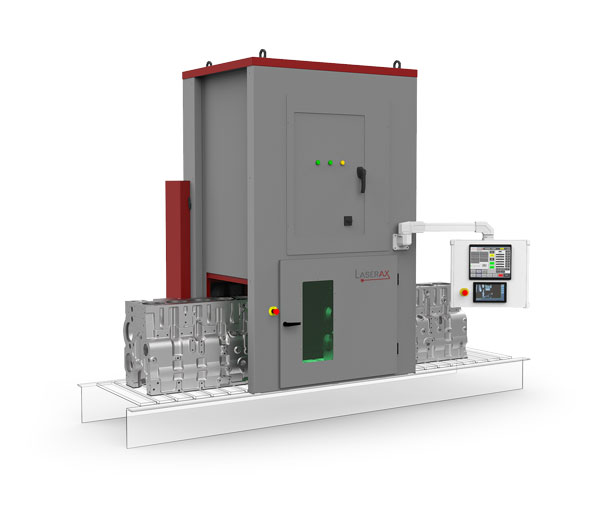

Conveyor Machine

Conveyor machines can account for all types of positioning variations that occur on conveyors. They can mark parts on the fly or while the conveyor is stopped for other processes like quality control, bundling, or weighting.

View Machine

Why Choose Fiber Laser Machines for Metal Marking?

-

Improve traceability

With a laser marking system, you get high-precision marks and a near-perfect readability rate. Unlike inkjet printing and dot peening, the readability of your codes won't degrade over time due to mechanical wear or clogging. The resulting marks are permanent and easy to read, providing a traceability solution you can rely on.

-

Prevent Bottlenecks

With laser powers ranging from 20W to 500W, laser marking won’t create a bottleneck in your production cycle. Our team also optimizes laser parameters for your specific application (repetition rate, line spacing, pulse energy, spot size, etc.) With these adjustments, we achieve a faster marking speed and a better contrast for your marks.

-

Reduce Maintenance

Laser technology is highly reliable and adapted to the most challenging industrial applications. Since fiber systems don’t have any moving parts or consumables, they require very little maintenance. Fiber laser components are also very durable, with a laser source that has a mean time between failures of 100,000 hours.

-

Guarantee Complete Safety

With Laserax, your work environment is 100% laser safe. Our machines are designed by experts who make sure they comply with all applicable safety standards. This way, you’re certain that your machine is safely integrated in your production line, and you don’t need to worry about additional safety measures.

Metals You Can Mark

Each type of metal absorbs light and conducts heat differently. Your metal part is thus at the core of choosing the right laser engraver for your application.

-

Aluminum

Since aluminum surfaces have a high thermal conductivity, fiber lasers can mark them at a high temperature for high-speed applications. Whereas laser etching is the fastest process, laser engraving is the most resistant.

Aluminum 380 and 6061 are the most common laser marked alloys, but all aluminum types can be marked. This includes die cast, general-purpose, pure, and anodized aluminum.

Aluminum parts: Die castings, coils, extrusions, billets, ingots, sows, rolling slabs, and more

Learn More -

Steel

Steel is a hard material that requires longer marking times than other metals. However, the marking speed can be increased by creating white marks instead of black ones. White marks contrast well with the bare steel color for most steel types.

For high-speed marking, laser etching is the best process for steel surfaces. To get the most resistant marks, laser engraving should be used. To increase corrosion resistance, laser annealing creates marks under the surface. You can laser mark any steel alloy, including anodized steel, carbon steel and die steel.

Steel parts: suspension springs, brake pads, coils, billets, plates, pipes, tubes, sheet steel, and more

Learn More -

Stainless Steel

Laser marking is most often used to mark stainless steel grades 304 and 316, but it can be used to mark any grade. The preferred marking method for stainless steel is laser annealing since it protects the chromium oxide layer on the metal surface. As a result, you get high-quality marks and prevent the formation of rust on the surface.

Stainless steel doesn’t require a high-power laser. This is because laser annealing works at lower energy levels than other marking processes.

Stainless steel parts: Fuel tanks, exhausts, suspensions, and other automotive parts

Learn More -

Anodized Aluminum

When marking anodized aluminum, you can either mark the bare aluminum (before the anodization process) or the anodized layer (after the process). In both cases, the part’s natural resistance to corrosion and abrasive wear is preserved.

Laser engraving machines create deep marks in the bare aluminum to ensure that the markings can be read after they’re anodized. Alternately, laser etching machines quickly etch high-quality marks on the oxide layer.

Learn More -

Magnesium

Magnesium has a lower density than other metals and is thus used for parts that need to be lightweight. Laser machines can be specifically configured to etch magnesium and magnesium alloys. Part of the material is removed from the surface, creating highly contrasted black and white marks.

Magnesium parts: Steering wheels, transmission cases, engine casings, engine blocks, other auto parts, magnesium ingots, bundles, billets, gearboxes, slugs, and die castings.

Learn More -

Lead

Lead and lead alloys have a low thermal conductivity, which means that most of the heat generated by laser marking remains on the surface. Lead materials also have a low melting temperature, making it easy for lasers to induce marks on a localized surface. For those reasons, the amount of energy required to etch lead is lower than other metals.

Lead part examples: cored stick anodes, ingots, and counterweights

Learn More -

Zinc

Zinc is not only used for its corrosion resistance, but also for its ability to be die casted. Laser etching is the only laser marking process that generates a high contrast on zinc parts. It can be used regardless of the zinc alloy, including brass.

Zinc part examples: ingot bundles, jumbo blocks, die cast ingots, anode ingots, slabs, die castings, automotive parts, and more

Learn More

Do You Need to Engrave a Different Material?

Contact usHow It Works: Laser Processes for Marking Metals

Once you get your machine, it’s already been configured by our experts with a specific marking process. Its configuration is mostly based on the metal being marked. For future applications, the same machine can be configured to mark different metals.

A machine’s configuration depends on its laser parameters. Examples of parameters that can be modified are laser power, movement speed, pulse duration, and number of laser passes. Here are the possible marking processes resulting from these configurations.

Laser Etching

Metal etching machines offer the fastest marking speed possible. For example, Laserax is able to etch high-quality data matrix codes on aluminum parts in just 1.40 seconds (for a 16x16 DMC of 10x10 mm; find out more about marking speeds for aluminum here).

This process is the best choice for most applications, unless you need increased resistance to surface treatments, corrosion, or wear and tear. In those cases, engraving or annealing will be better adapted to your application.

You can laser etch: Steel, Aluminum, Anodized Aluminum, Lead, Magnesium, Zinc

Laser Engraving

Laser engraving machines generate marks that are deep enough to resist abrasion and most surface treatments. When engraving metals with this process, you can implement traceability earlier in the production process. Examples of metal laser engraving are VIN markings and shotblast resistant markings.

You can laser engrave: Steel, Aluminum, Anodized Aluminum (before anodization)

Laser Annealing

Laser annealing is used to avoid any damage to the part surface, as it is the only process that does not use laser ablation. Instead, it triggers a chemical reaction that creates marks under the material’s surface. This method is useful for parts like stainless steel exhaust lines, which must keep a high resistance to corrosion.

You can laser anneal: Steel, Stainless Steel, Chrome Plating

Deep Laser Engraving

As the name suggests, deep engraving creates markings with smooth edges that are much deeper than regular engravings. This process is typically used for applications that have depth and aesthetic requirements. Some examples include logos, stamping plates, and mold inserts. The engraving speed varies based on the laser power, the material, and the line width.

You can deep engrave: Steel, Stainless Steel, Aluminum

Laser Machine FAQs

-

What’s the difference between CO2 lasers and fiber lasers?

CO2 laser marking machines produce a different wavelength than fiber lasers. As a result, fiber lasers are quite efficient at marking most metal surfaces, whereas CO2 lasers are better at marking non-metal (organic) materials like wood and plastics.

Read more on the subject: CO2 vs. Fiber Laser - Which One Should You Buy?

-

Can a CO2 Laser Engrave Metals?

CO2 lasers cannot engrave metals, but they can still leave permanent marks. This is because CO2 wavelengths do not react with metal materials. As a result, the surface needs to be covered by a special marking spray that forms a strong chemical bond with the metal when hit by laser light.

Operators need to apply the spray manually and allow it to dry before marking, adding extra steps and consumables to the operation. For these reasons, part manufacturers usually prefer fiber laser engravers, the solution offered by Laserax for metal engraving.

Read more on the subject: How to Choose the Best Fiber Laser Engraver

-

What’s the difference between laser cutting and laser engraving?

Laser cutting uses laser technology to cut materials whereas laser engraving is focused on marking. Laser cutters use continuous-wave lasers, whereas laser engravers use pulsed laser beams. The engraving process rarely exceeds 100W, but it reaches higher peaks of energy. Laser cutting machines can continuously function at 6,000W of laser power while laser engravers can create peaks of 10,000W.

-

Should I engrave QR codes or data matrix codes?

QR code laser marking is used in many applications. Yet, data matrix codes offer an important advantage when compared to QR codes. They’re capable of encoding more characters in the same space, which often means faster marking speeds.

Read more on the subject: Data Matrix Codes vs. QR Codes - What Is the Difference?

-

How much does a laser machine cost?

Many factors affect the price range of a laser machine, such as the laser system, the laser head, the automation level, the laser options, the laser power, and the laser equipment. High-power lasers, for example, are faster but more expensive. Prices also vary from one manufacturer to the other based on several factors, such as the quality of the optical components they use, or the expertise and service they offer.

Read more on the subject: How Much Does a Laser Etching Machine Cost?

-

How long does it take to mark with a laser?

Industrial lasers can achieve permanent results quickly. In most cases, the difference between one marking application and another is a matter of seconds. The marking time depends on three key factors:

- Material: Engraving a hard material requires more time and energy

- Color: Pitch-black markings take more time than shades of gray

- Power: The more powerful the laser, the faster the marking speed