FREE STANDING LASER ENCLOSURE

Laserax enclosed laser marking machines offer a safe and reliable industrial solution for marking a wide array of materials such as: aluminum, steel, lead, magnesium, copper and several plastics from Kevlar and nylon to polyethylene and PVC. The enclosed laser marker can mark components and finished goods. Laser Direct Part Marking (DPM) is a very efficient way to permanently identify parts.

Laserax freestanding safety enclosures satisfy all of the following requirements :

- Designed for Class 1 applications

- Enclosure is adapted to all Laserax products

- Enclosure sizes can be adapted to your requirements

FREE STANDING LASER ENCLOSURE ADVANTAGES

RUGGEDNESS

Laserax’s enclosed laser cells are designed to withstand the most demanding industrial environments.

FLEXIBLE WORK CELL

Our free-standing laser enclosures are particularly well adapted for applications with other machines such as lathes, milling machines and grinders.

MULTIPLE OPTIONS

These free-standing laser cells can be used with robots or positioning jigs. Or you can rely on Laserax’s vision system to adapt the laser parameters to the position and geometry of the parts. This gives the clearest marks every time.

SAFETY

Laserax’s laser marking workstations are designed for Class 1 applications. They are among the safest laser marking systems in the industry. People working at the workstation or close to it will not require any personal safety equipment and no special precautions are required of them.

WANT TO LEARN MORE ABOUT ENCLOSED CELLS FOR LASER MARKING ?

ASK AN EXPERTProducts and options

Products

Laserax laser marking enclosures are available for the following products :

Applications

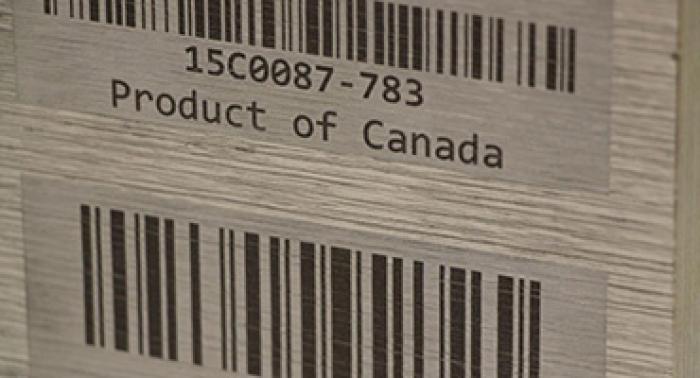

Part Traceability

Our free-standing enclosure is part of a complete part traceability system. Laser markers can be used to etch text, logos, barcodes and 2D codes such as Data Matrix Codes directly on the surface of most material.

Learn moreIndustrial Marking

With industrial laser markers it is possible to identify parts made of a wide range of materials. These markings can be used by any stakeholders to retrieve information about the products. Laser Direct Part Marking (DPM) is part of the ultimate traceability system.

Learn moreLaser cleaning and rust removal

Laser cleaning, rust removal and surface preparation are innovative and effective industrial processes. The laser removes contaminants on most metal types.

Learn moreIndustries

Aluminum industry laser applications

Welcome to error proof traceability where you can imprint a permanent heat resistant identifier directly on aluminum without consumables.

Learn more

Extrusion Industry Laser Applications

With growing traceability standards throughout the aluminum value chain, the introduction of industrial laser etching systems becomes a must.

Learn more

Manufacturing industry Laser Applications

Whether it’s for reducing costs or adding value to your products, lasers can provide huge return on investment in a wide range of manufacturing applications.

Learn more