Industrial Laser Marking Service

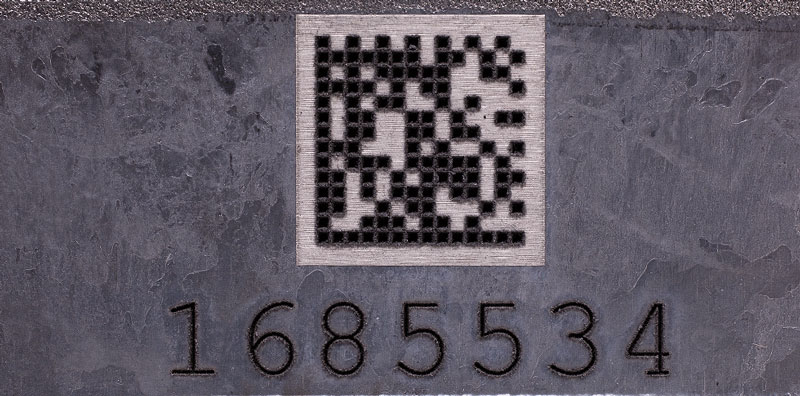

With our laser marking service, you can permanently mark parts with barcodes, data matrix codes, QR codes, serial numbers, logos, and other types of identifiers. Our fiber lasers can be used to mark a range of materials, such as:

|

|

You can send batches of parts to be marked at Laserax, or we can come to you if parts are too heavy or

large

for shipping. Our laser marking service is ideal if you need to start producing while waiting for a laser marking machine order, or if you have a short term marking need.

Our Laser Marking Services

Laser Marking for Traceability

Detailed Reports

You get a comprehensive report, which can include barcode quality reports, engraving depth measurements (obtained using a 3D camera or a high-resolution optical microscope), microstructure analysis, marking speeds at different laser power levels, as well as videos and photos of the marking operation.

Post-Process Resistance

If you need a marking process that maintains traceability after a surface treatment (such as e-coating, powder coating, heat treatments, or shotblasting), we can develop that process for you. We can also analyze the quality of the markings after the surface treatment to provide the grade quality of the code.

Custom Tooling

To ensure consistent part positioning, we can design and build custom fixtures to hold your parts into position. If you decide to buy a machine in the future, you will be able to reuse our design and fixtures in your production line.

|

Consider Renting a Laser Marking MachineShipping costs can add up quickly. If you have a large number of parts to mark, it may be more cost effective to rent a laser marking machine. |

Additional Resources on Laser Marking

|

How Barcodes WorkThis eBook explains the difference between 1D codes, QR codes, and data matrix codes. It also explains how barcodes work and the importance of databases. |

|

How Does Laser Marking Work in 5 StepsThis article explains how laser beams interact with metal surfaces during laser marking. It also explains the difference between fiber lasers and CO2 lasers, the different laser marking processes, and how pulsed laser beams achieve higher energy levels to ablate materials. |