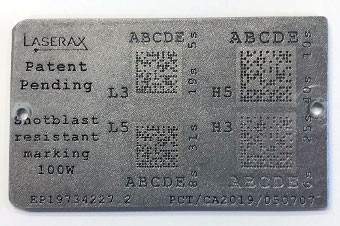

Shotblast Resistant Laser Marking

Faced with evolving traceability requirements and regulations, many automotive OEMs and parts suppliers are searching for ways to implement traceability before shotblasting. Since traditional direct part marking isn’t enough, we’ve developed a marking technology that protects 2D codes from shotblasting.

If you need an inline solution, we’ve optimized the marking speed, making sure it keeps up with short cycle times. Die casted parts can now maintain complete traceability—from the extraction of the die all the way to the assembly line.

Contact Us