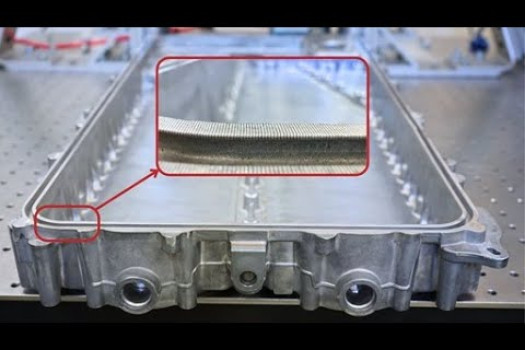

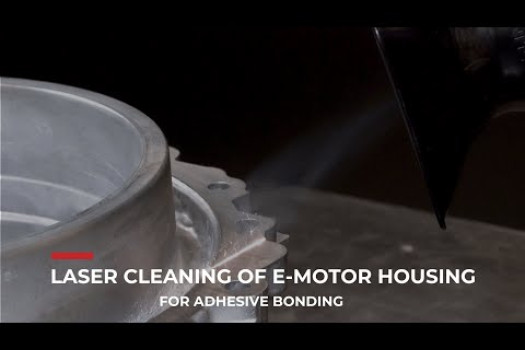

Laser Surface Preparation For Adhesive Bonding

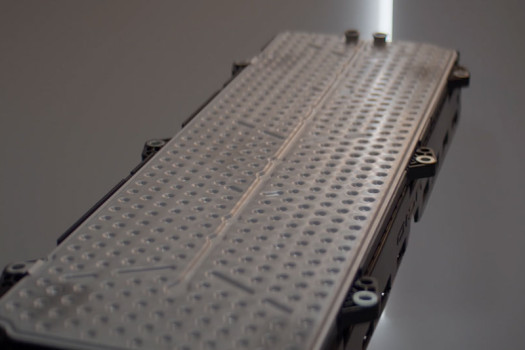

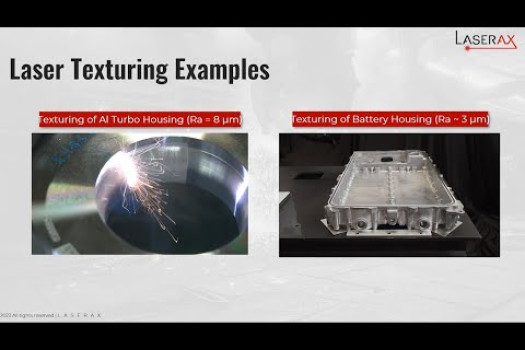

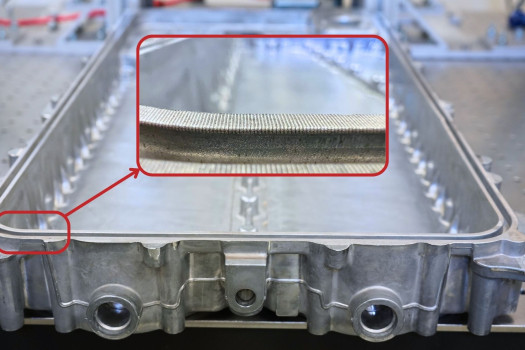

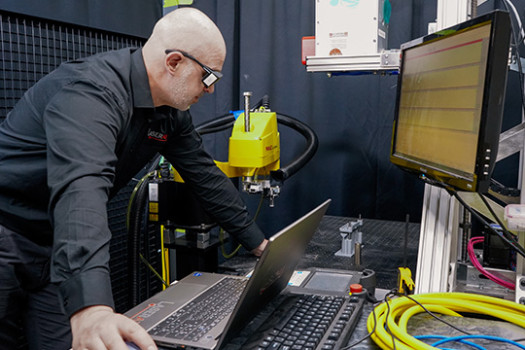

Laser surface preparation is a fast, precise, and repeatable process. It allows manufacturers to scale up production and ensure the highest level of quality. It is used to prepare metal surfaces for bonding with thermal adhesives, structural adhesives, and other types of adhesives.

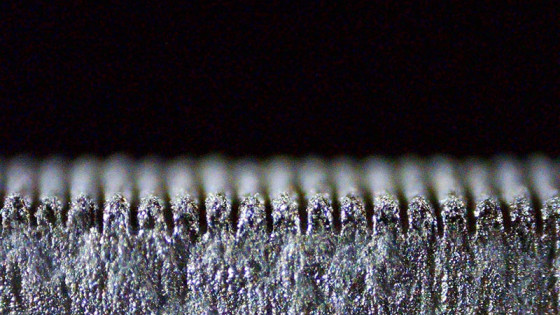

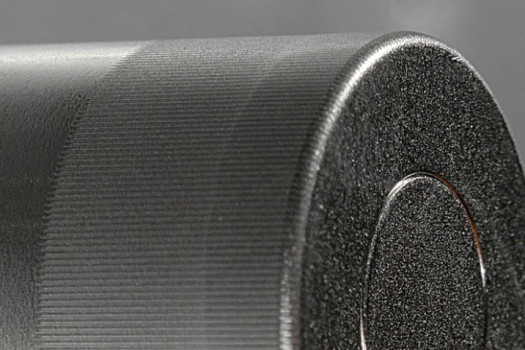

Using fiber lasers, you can remove contaminants, change the surface roughness, and modify the chemical composition of the surface to drastically improve the adhesive bond strength.