Fuel Cell Manufacturing With Laser Technology

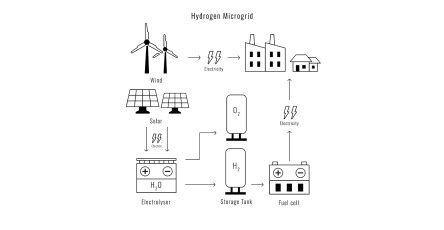

Fuel cells are a promising solution for a greener future. They can play an important role to power commercial electric vehicles and facilities.

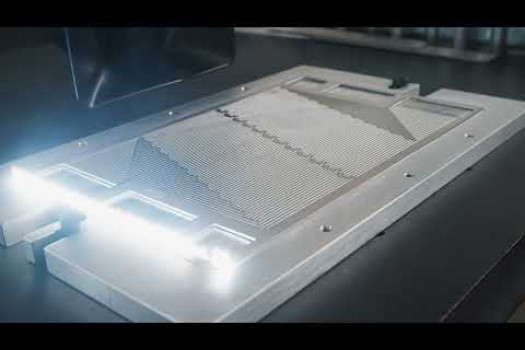

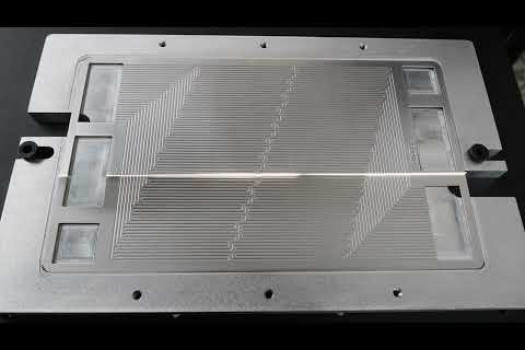

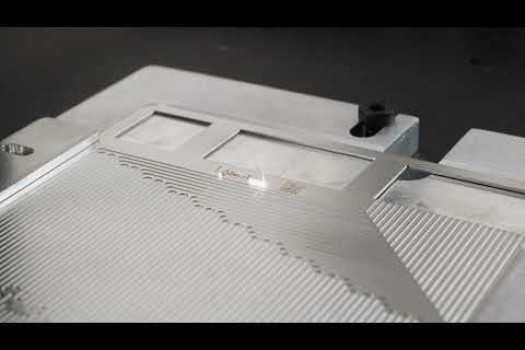

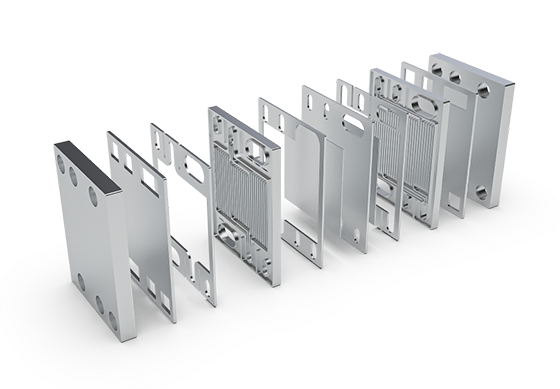

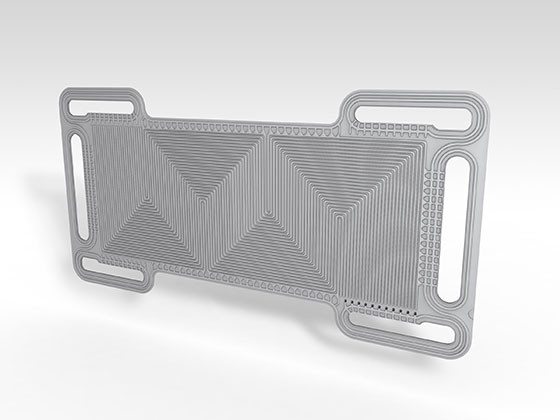

During fuel cell manufacturing, bipolar plates (also known as flow plates or interconnects) can benefit from laser surface preparation. Laser texturing and cleaning can prepare these plates for various protective coatings and adhesives with precision, speed, and cost efficiency. The same laser can also be used to mark plates for traceability.