On-site Laser Safety Certification

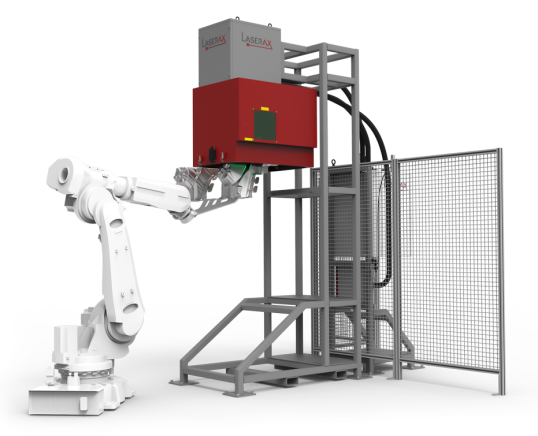

Laserax can visit your facility and make the necessary changes so you meet class-1 laser safety standards (such as ANSI Z136.1, FDA CFR 1040-10, and IEC 60825). With this certification, you won’t need additional safety control measures or personal protective equipment.

You can use this service to:

- Bring unsafe installations up to standard

- Validate the laser safety of your installation

- Review modifications made to a laser machine

- Assist a system integrator with laser safety

- Remove liability from your hands

- Receive laser safety training on best practices for laser use

- Have the documentation needed to prove to organizations regulating laser safety (like the FDA) that your installations comply with their requirements