Laser Machine Options

Laser Power

The machine is powered by a fiber laser whose power can range from 20W to 500W. A higher power increases the surface treatment speed, allowing you to meet more challenging cycle times or reduce your operator’s waiting time.

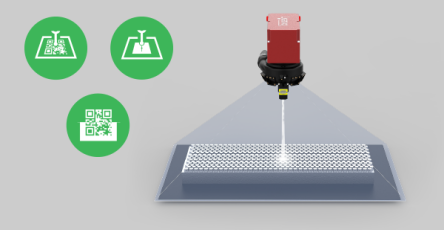

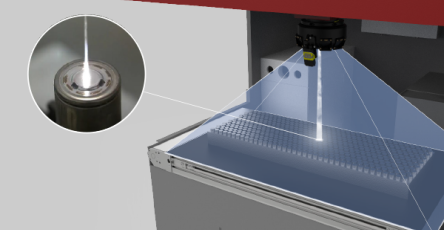

We also offer two types of laser heads. 2D heads are typically used for surface treatments on flat surfaces while 3D heads can be used to treat any types of surface geometries, including curved ones, or to treat surfaces at different heights without moving the head.

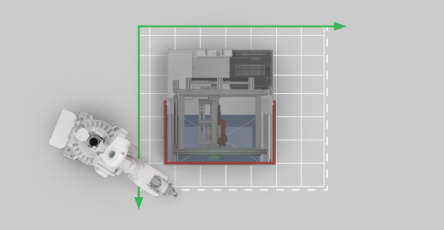

Gantry System

The laser head can be mounted on a gantry system to clean or texture large modules and reach all battery cells and busbars—all of this within a single sequence.

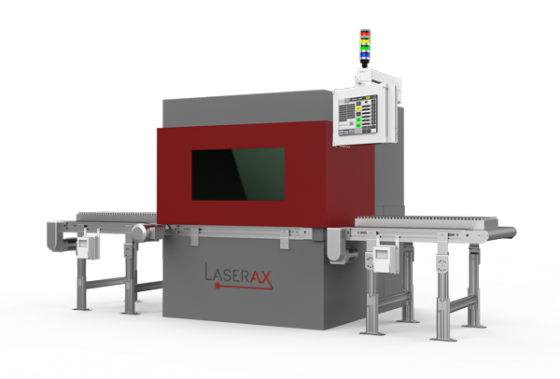

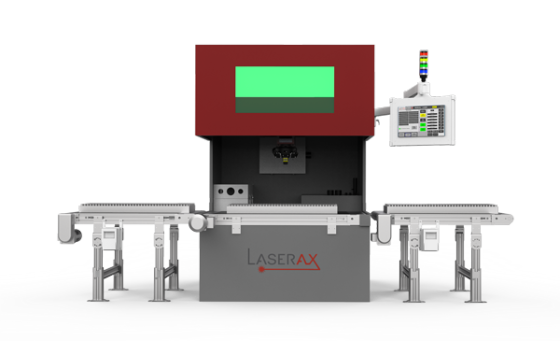

HMI Control Panel

The standard HMI control panel provides direct access to laser parameters near the machine. You can:

- Set laser parameters

- Enter the manual operation mode to run validation tests or calibrate the laser

- Display information such as the system status and the operation mode

If you want to add custom features in the HMI, contact us.

Battery Positioning Validation

Our cameras can validate whether modules are in the right position before beginning the cleaning operation. They can measure all individual cell locations and adjust the laser cleaning positions accordingly.

Custom Fixtures

Our team can build custom fixtures to fix modules into position.

Fixture Validation

Leave no room for operation mistakes that lead to poor surface treatment performance. If you are using multiple part models, our fixture validation system can automatically read the fixture’s barcode and load its corresponding parameters.

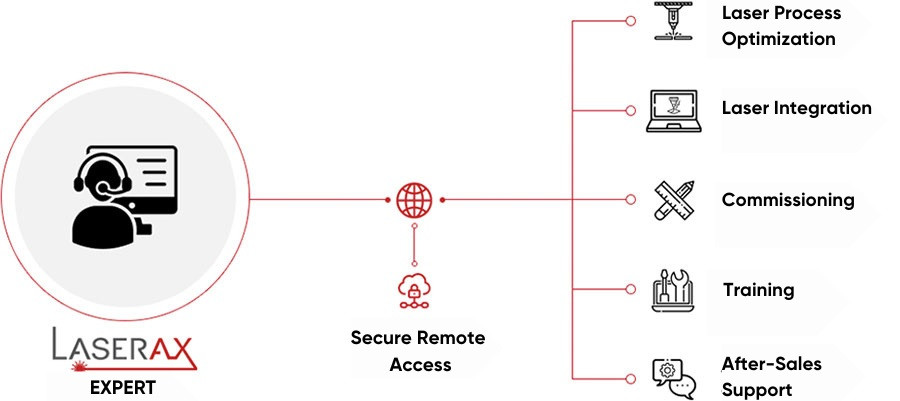

For more machine options, contact a Laserax expert.