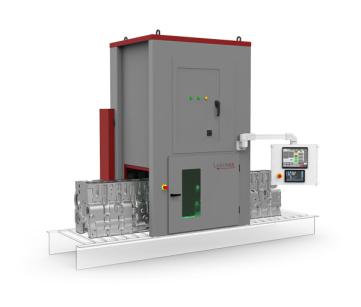

INdustrial Laser Solutions For Electric Motor Manufacturing

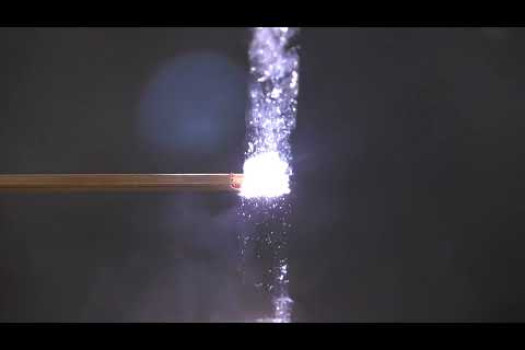

Laser technology is quickly becoming a standard in the EV industry, as electric motor manufacturers need to scale up production, lower their environmental impact, and consistently produce high-quality parts.

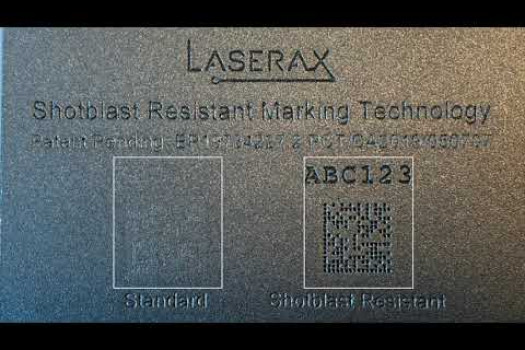

Parts like stators, hairpins, rotors, and a range of castings are already manufactured using lasers. Whether it’s for laser marking or laser cleaning, Laserax has developed a range of laser solutions specifically for electric motor manufacturers.