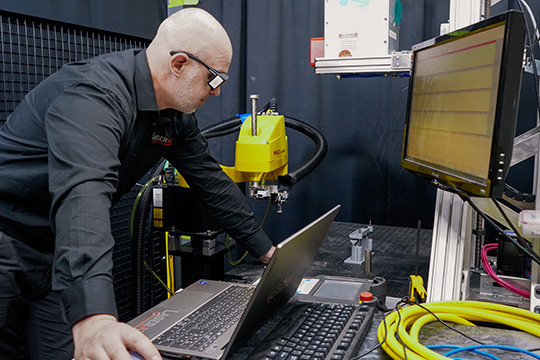

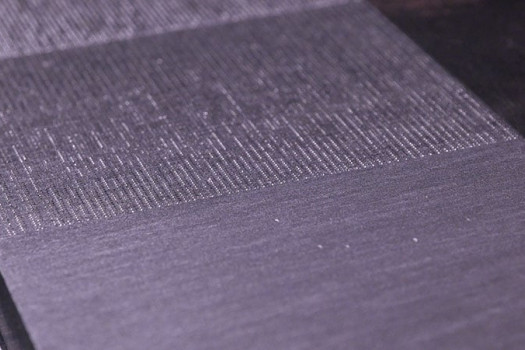

Laser Texturing Service

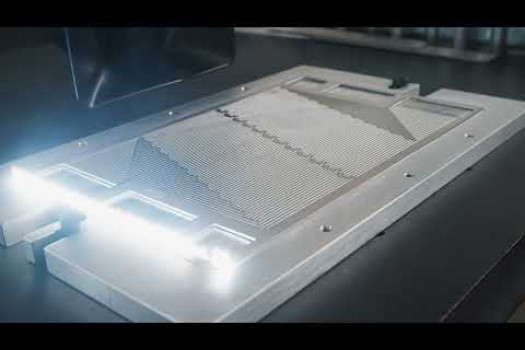

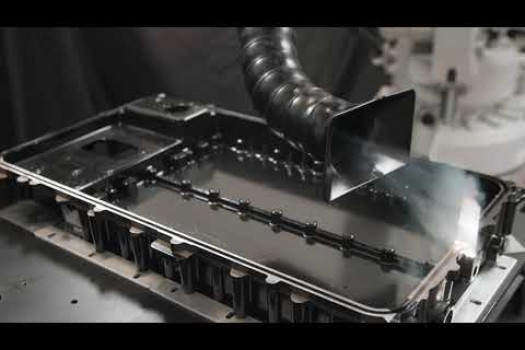

Our laser texturing service is a great solution for manufacturers looking to explore the benefits of laser texturing for a specific metal part and validate whether it works in their manufacturing process. It can also be used to meet temporary production needs. For example, we can texture small batches of parts for preproduction, prototyping, or while you wait for a laser texturing machine order.

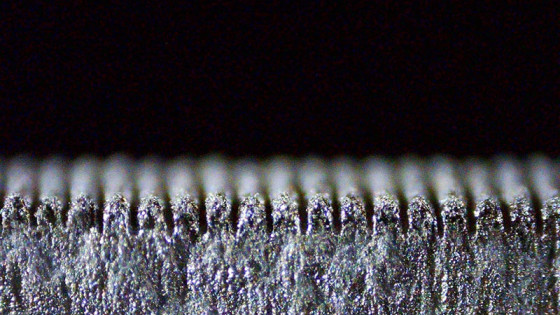

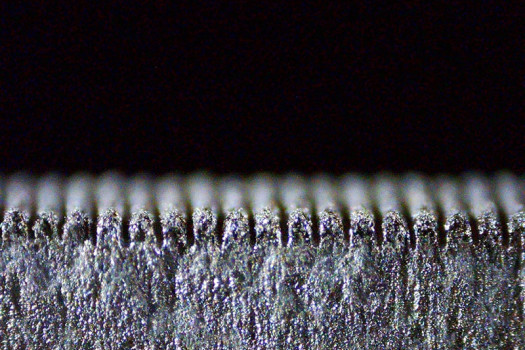

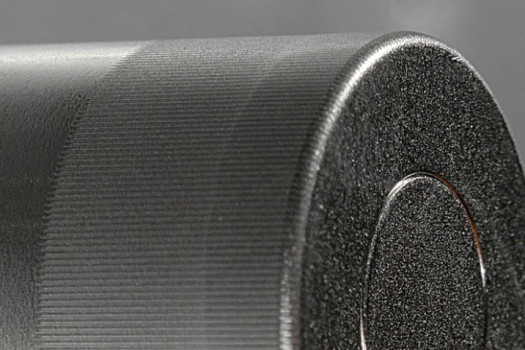

Laser texturing offers new possibilities to manufacturers wanting to improve surface preparation. It can be used to:

- Eliminate the need for masking

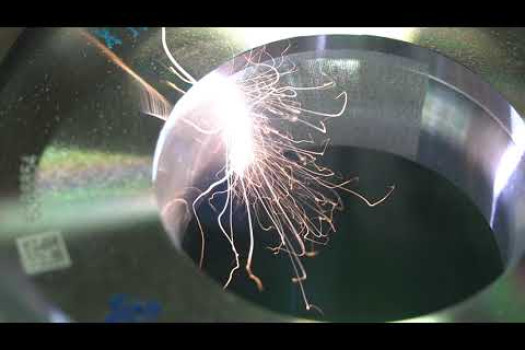

- Get rid of abrasive media and dust that contaminate surfaces

- Remove surface contaminants like oil and oxides

- Prevent critical damage to metal surfaces

- Obtain better adhesive properties

- Scale up production with a faster process