Battery Laser Texturing

Texturing For Bonding

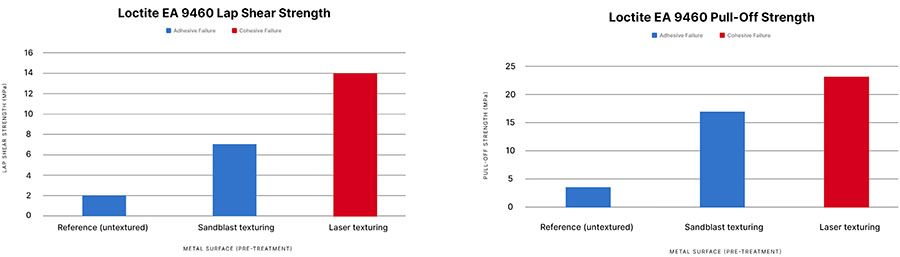

Laser texturing significantly improves the bond strength compared to mechanical surface preparation techniques because it generates both chemical and mechanical changes on the surface. The system’s parameters can be optimized to generate different surface roughness levels and patterns based on each application requirements.

Laser texturing is used to clean and texture surfaces prior to enhance it’s bonding properties. For adhesive bonding applications, laser texturing provides a higher surface roughness, increasing the effective bonding surface area of the joint and its overall strength. The laser process can be configured to meet any surface roughness requirements with high accuracy and repeatability.

This technology is highly precise and can either be fully or semi- automated. It is a great alternative to other surface preparation methods such as chemicals, abrasives, and grit blasting.

Benefits:

- No abrasive media

- Lower operative costs

- Lower maintenance

- Personalized surface patterns and roughness values

- Safer

- Easily automated

- Repeatable

- No wear

- No contaminants