Industrial Laser Welding Machines

When it comes to welding metals like aluminum, steel, copper, and various alloys, laser welding machines are ideal due to their speed and precision. Whether you need a manual or automated laser solution, our team of laser experts can help you integrate it in your production line.

Our solutions are also used in R&D for process and product development.

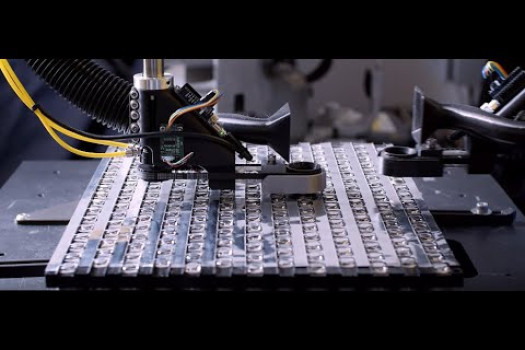

Scale Up Production

Our laser machines are built to scale up production and meet demanding requirements. They include features such as vision, robot arms and a large field of view to optimize the laser welding process for high-speed production.

Improve Weld Quality

Laser welding is superior to traditional welding technologies like ultrasonic bonding, TIG welding, and resistance welding. With laser weld monitoring devices, it’s easy to detect and rework defects immediately.

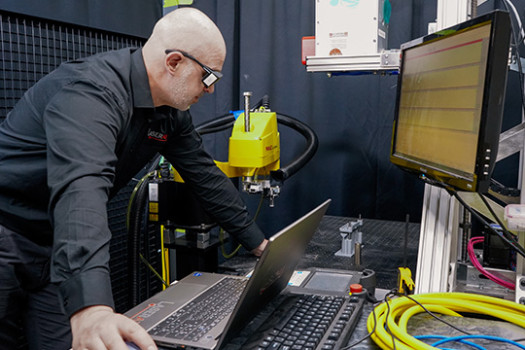

Get Tailored Integration Services

Our laser welding experts perform tests, develop the welding process with you, and help you integrate your laser welding machine.