Battery Laser Welding Workstation

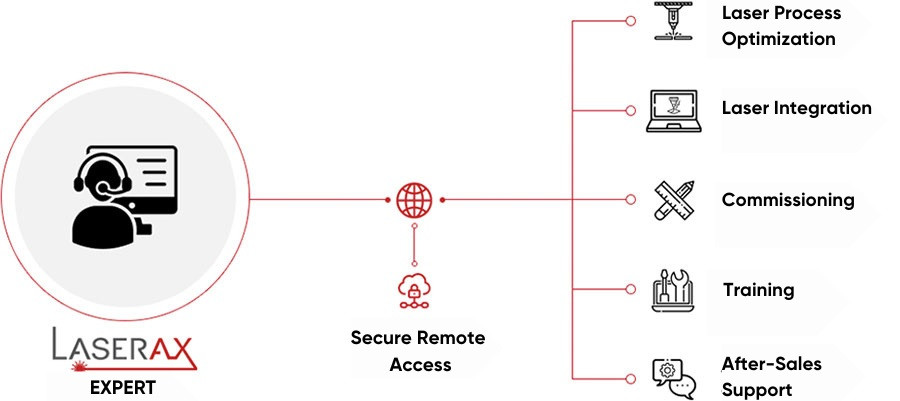

Easy to operate, this workstation is ideal to support your R&D team, develop your laser welding process, and start making small production batches. Our battery and laser welding experts will guide you and help you speed things—even before the workstation is delivered.

The workstation is designed to ensure a smooth transition when you need to scale up and automate production. On that day, you will be able to use the same laser configuration so that the process you developed is 100% compatible in the automated production line.