Advanced Laser Solutions for

Next-Gen Manufacturing

Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions.

Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions.

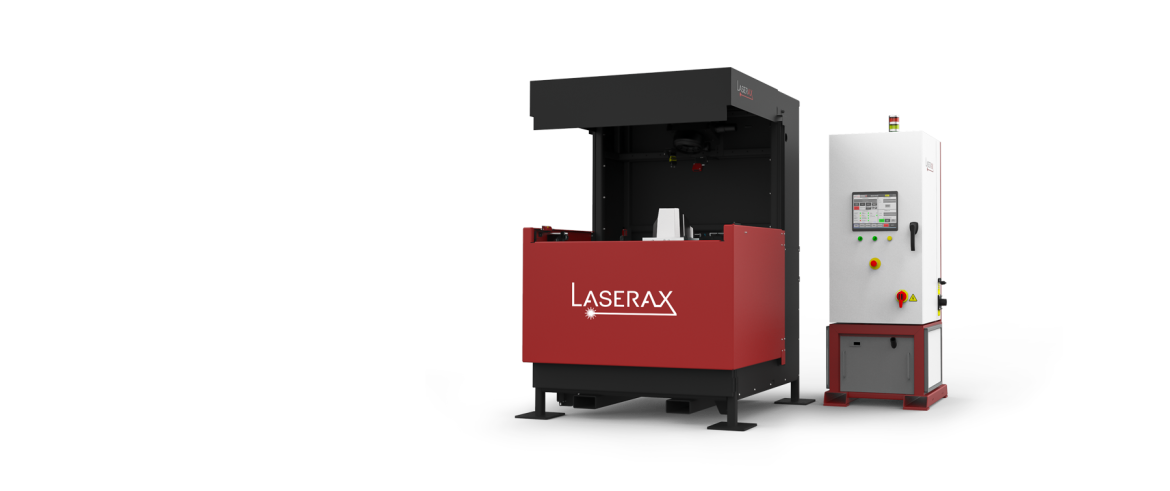

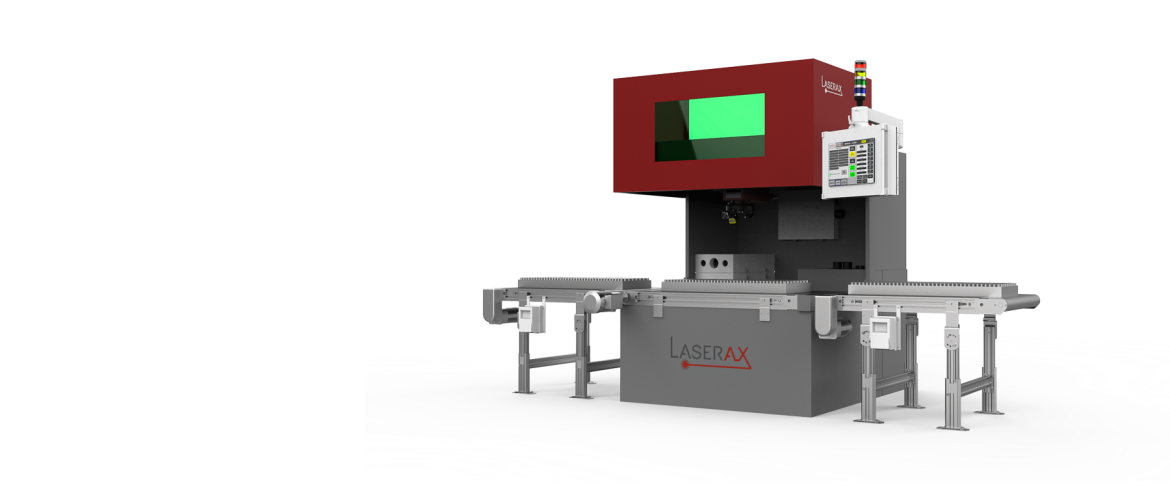

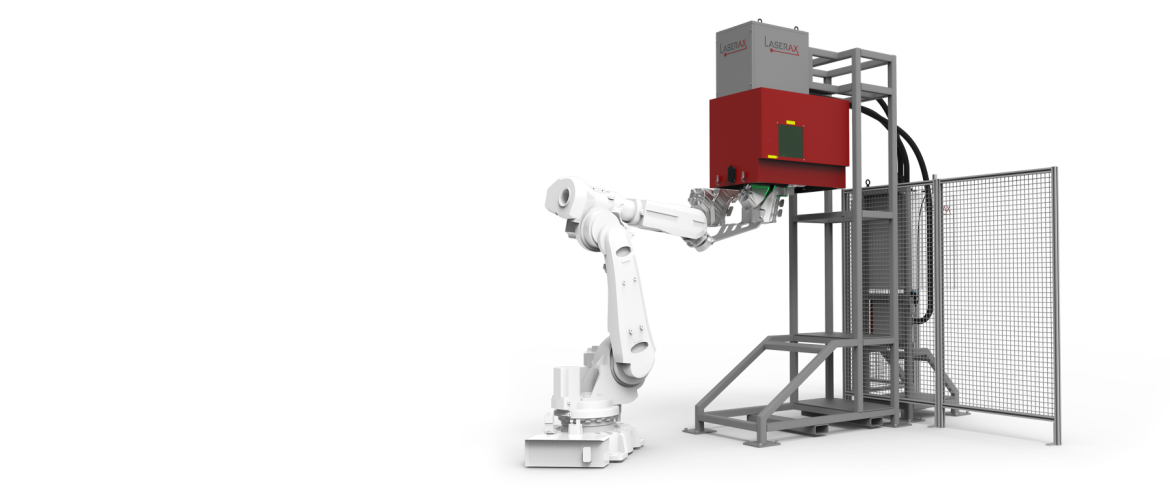

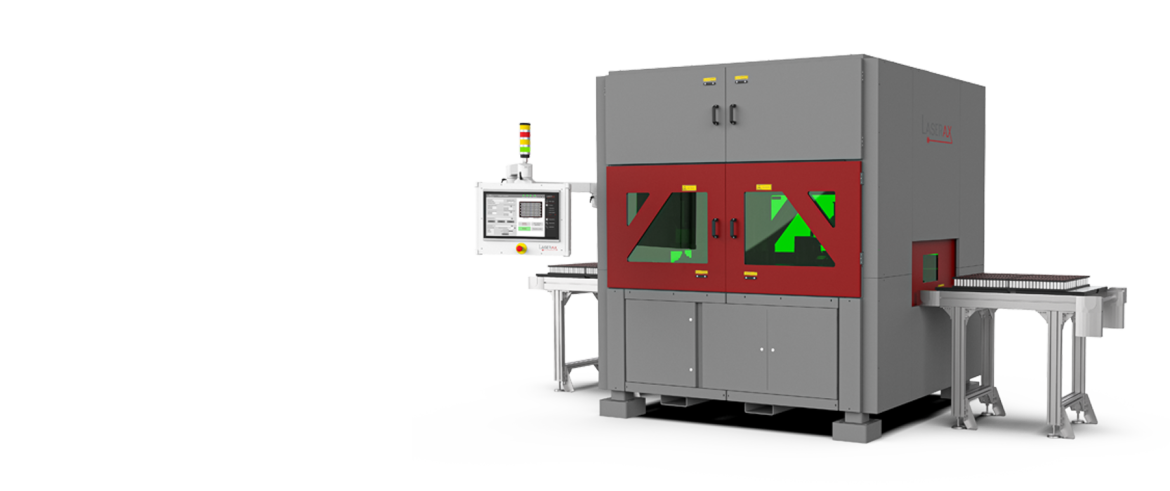

Our laser cleaning machines are complete solutions with fume extraction, laser safety, performance optimization, and more. They are ready for robot lines, conveyor lines, or manual loading by operators. In high-volume production lines, they provide a high return on investment and achieve superior cleaning and texturing quality.

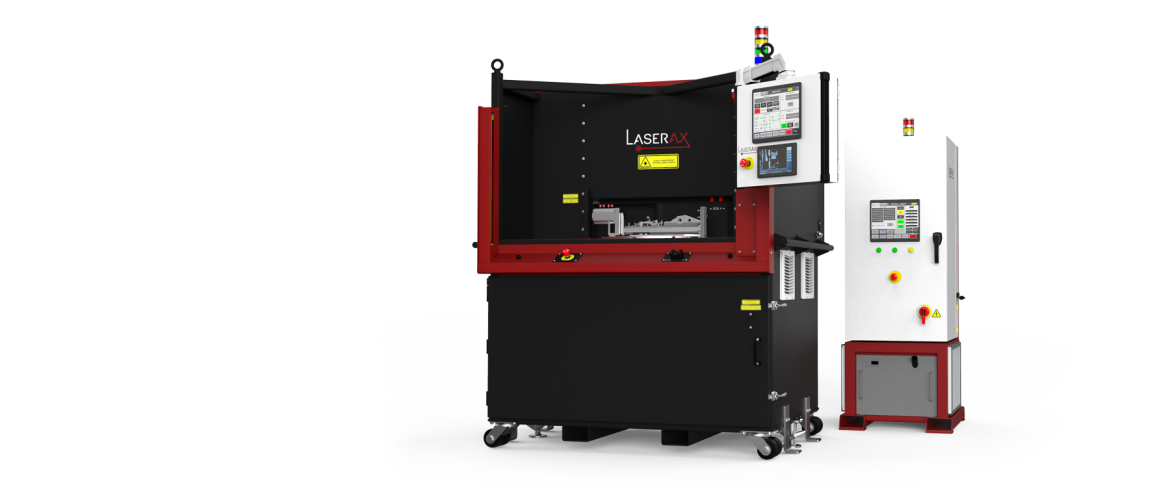

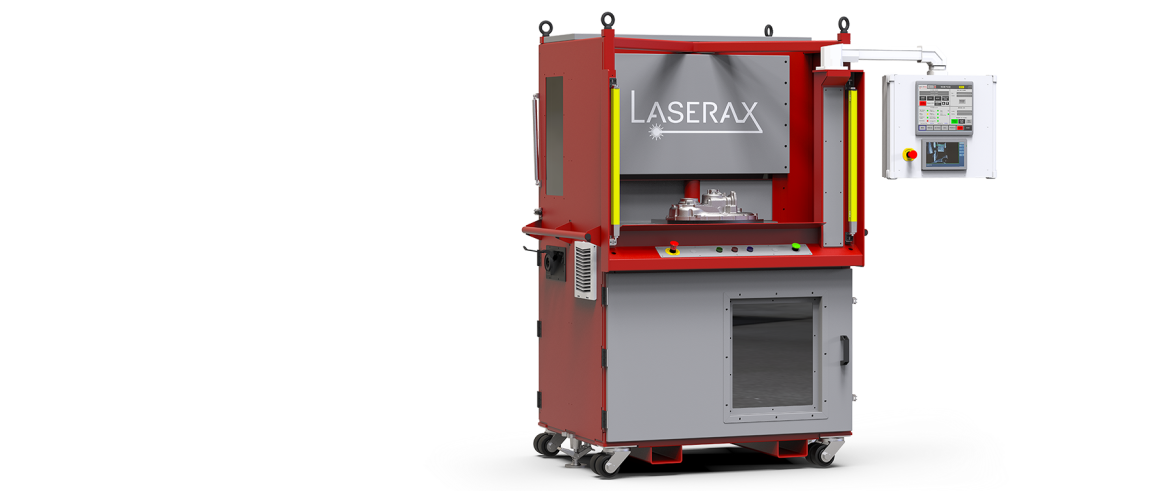

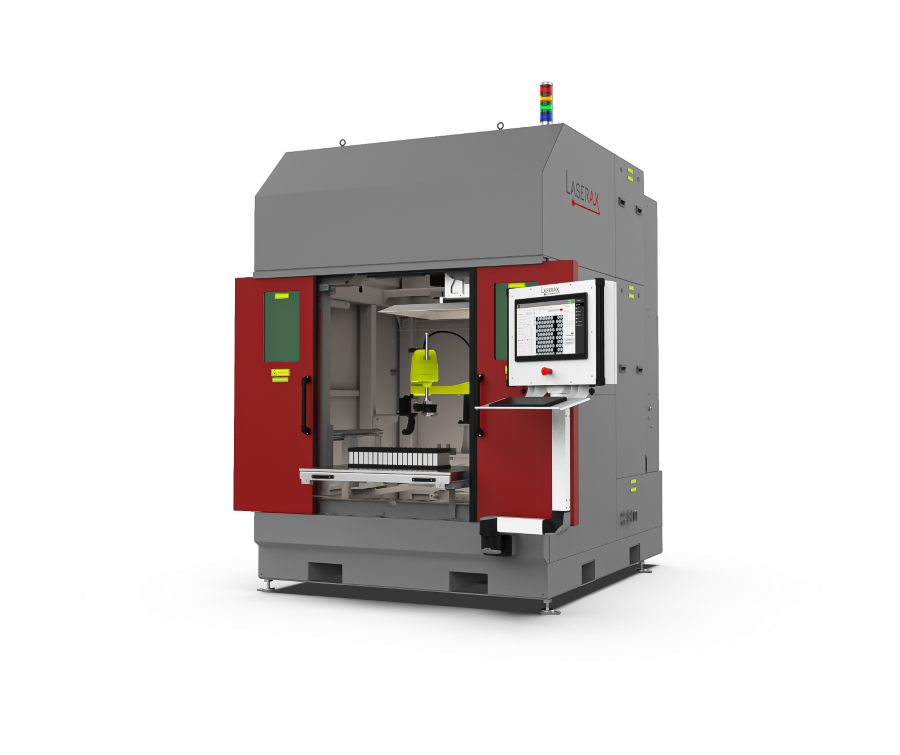

Class-1 certified, our laser marking machines are complete solutions ready for robots, conveyors, or manual loading. Each machine is designed to address specific challenges, whether you need to minimize the impact on cycle time, mark multiple parts, minimize the machine’s footprint, or manage part positioning variations.

Designed for battery welding applications, our laser welding machines can be used for R&D or full-scale production. They are powered by continuous wave lasers of up to 2000W, enabling high-speed welding for both cylindrical and prismatic battery pack designs.

Our laser cleaning systems are designed for automated and semi automated production lines. Offering up to 3kW, they provide the speed and precision needed for short cycle times. They can clean and texture surfaces in a single operation, and process moving parts with no impact on quality.

Our OEM laser markers come with a wide range of options to make sure they meet your requirements. Ranging from 20W to 500W, they can mark at high speed and operate in a large marking field. When you contact us, our application specialists will make sure to capture all your requirements, including lead times and AIM-DPM specifications.

Clear dental aligners have changed the way dentists and orthodontists straighten teeth. Rather than metal braces, these transparent plastic trays are digitally designed. Each is custom-made for every patient, making accurate identification and traceability critical.

The industrial laser marking sector has undergone significant consolidation and technological advances over the past few years. What started as an alternative to traditional marking methods has now become the standard for permanent product identification across automotive, aerospace, medical device, electronics manufacturing, and other industries.

Although steel is a strong metal, altering its microstructure with a surface treatment can be necessary to improve hardness and wear resistance. In other cases, surfaces must be cleaned to remove oxides, textured to improve adhesion, or coated for protection.