Laser Marking Expertise For Smelting Plants

To address tough conditions in smelting plants, we’ve developed robust solutions that can withstand heavy dust and high temperatures as well as keep up with short cycle times.

Permanent and packed with information, identifiers will maintain traceability however challenging the environment may be. Our lasers can engrave durable markings on all types of surfaces, including rough & curved ones, as well as surfaces with water or cutting oil on them.

- Fastest marking

- High positioning tolerance

- Heat-treatment resistant

- Automated solutions

- Industrial-grade equipment

- Class 1 laser

- No consumables

- Low maintenance

Let Us Know Your Application

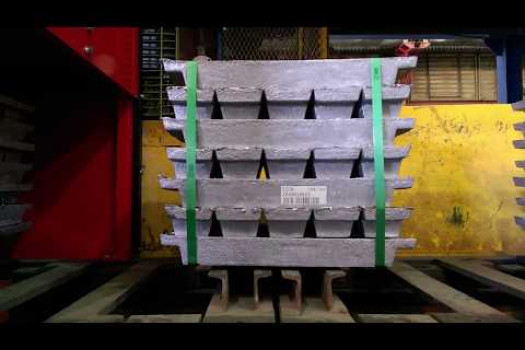

Applications In The Metals Industry

Laserax has earned the trust of metal smelters all over the world by successfully deploying more than 30 traceability solutions in their plants. Metal smelters use our technology to mark all types of semi-finished castings, including:

- Billets

- Sows

- Rolling ingots

- Foundry ingots

- T-ingots

- Bundles

- Anode rods

- Slabs

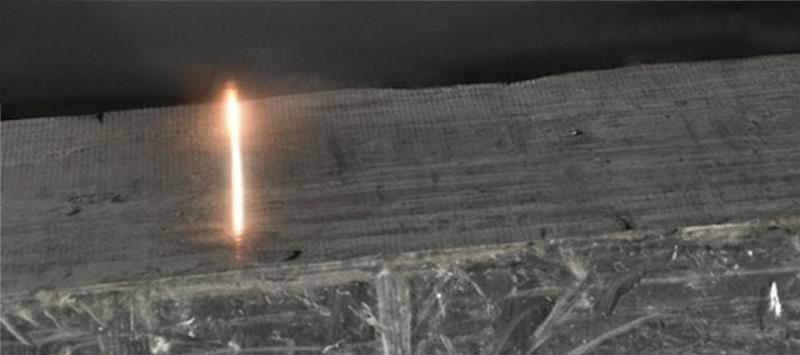

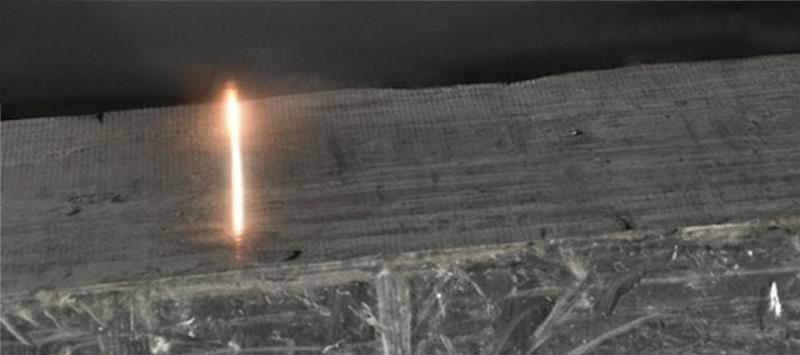

Laser Cleaning To Remove Oxides

Laser cleaning offers possibilities that were previously nonexistent for metal smelters, including precise oxide removal from aluminum anode rods. Unlike abrasive blasting methods that remove excessive material, laser cleaning eliminates oxides and baked-on bath residue while leaving the base material completely intact. This chemical-free process ensures a consistently clean anode rod surface before each cycle, delivers repeatable results with minimal maintenance, extends equipment life, and improves overall smelting efficiency. For high-value alloys, this precision translates into a significant return on investment. Additional applications include laser paint removal and laser rust removal.