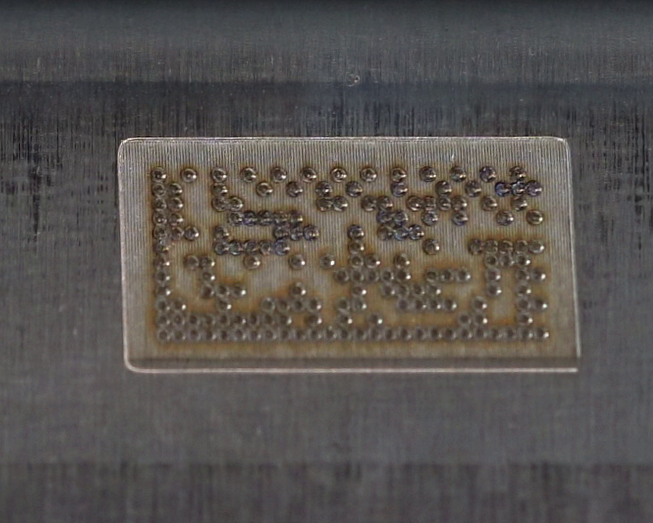

E-COAT RESISTANT LASER MARKING

Coatings can make identifiers unreadable and affect your ability to achieve cradle-to-grave traceability. Because traditional masking methods are slow and error-prone, we’ve developed a laser marking technology that makes identifiers readable after e-coating.

This enables manufacturers to mark parts early in the production process with a single, unique code, allowing for full lifecycle traceability. Our industrial-grade systems are designed to operate reliably in demanding industrial environments, making Laserax the benchmark for laser marking in automotive applications.

Contact Us