De-Risking Battery Welding Scale-Up and Replacing Wire Bonding

When our client Scania set out to build a greener world and revolutionize the battery industry, they needed a partner who could keep up with their ambitious goals.

Read more

When our client Scania set out to build a greener world and revolutionize the battery industry, they needed a partner who could keep up with their ambitious goals.

Read more

A world-leading Tier 1 OEM in the automotive industry sought to optimize the manufacturing process of powertrain and structural components by enhancing the surface preparation step for those critical metal parts.

Read more

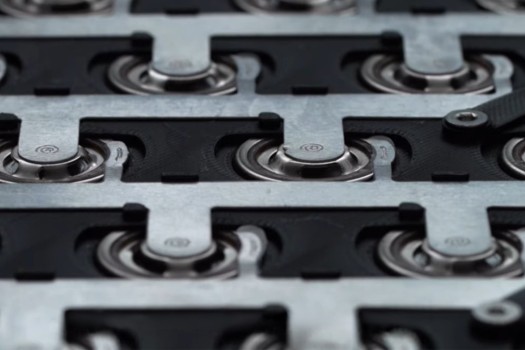

A leading Tier 1 OEM in the EV battery industry faced a critical problem in their manufacturing process: contamination on battery cell terminals was causing defects during their ultrasonic wire bonding process to create connections between busbars and cells.

Read more

Meridian is a leader in magnesium die castings. With manufacturing facilities at key locations in Canada, the USA, the UK, Germany, China, and Mexico, they provide automotive OEMs all around the world with lightweight die castings.

Read more

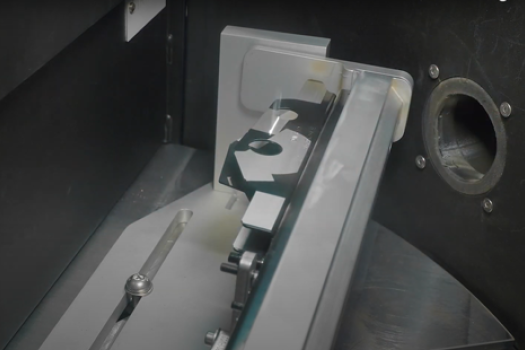

During the development of their new product, this manufacturer used grit blasting to prepare metal surfaces for a coating process. After they changed their part design, grit blasting caused defects and was no longer suitable.

Read more

Our client is specialized in seating solutions for the automotive industry. Their seat rails—as part of critical safety components—are e-coated to prevent corrosion and maintain the seat’s structural integrity. In the fabrication of these parts, there must be no traces of e-coating near the welding joints.

Read more

In Inovaweld’s production line, more than 40,000 stainless steel barrels can be manufactured in a single year. As part of their manufacturing process, they must clean stainless steel to remove oxides from welding joints (including butt joints and lap joints). Once stainless steel is cleaned, they must make sure that it is passivated to protect it from corrosion.

Read more