Laser Texturing

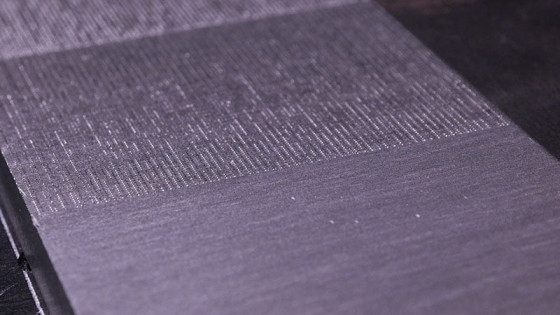

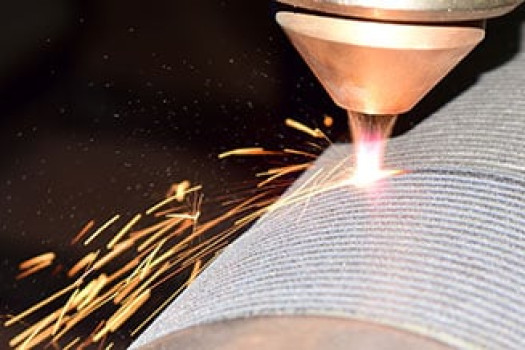

Laser texturing is a process that alters a material’s surface properties by modifying its texture and roughness. The laser beam creates micropatterns on the surface through laser ablation, removing layers with micrometer precision and perfect repeatability. Typical patterns include dimples, grooves, and free forms.

Laser surface texturing can be used to improve properties like adherence, wettability, electrical and thermal conductivity, and friction. For example, you can increase surface adherence before applying common coatings like adhesives, paint or ceramic. Laser texturing can also be used to prepare surfaces for thermal spray coating and laser cladding as well as to improve the performance of mechanical seals.