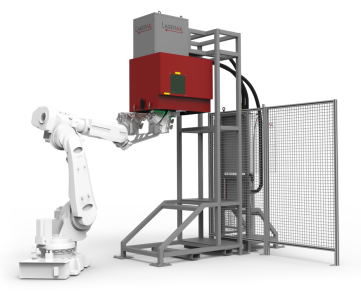

Industrial Laser Solutions For Foundries & Casting Plants

To reduce the size of recalls, new automotive OEM programs are requiring foundries and casting plants to improve their traceability capabilities. To apply to these programs, you often need to:

- Mark parts as soon as they’re created to achieve 100% traceability

- Replace batch numbers with a unique serial number for each casting

- Mark a unique identifier into each sand mold

- Mark castings to be shotblasted or e-coated

- Perform fast inline identification to prevent slowdowns in production

- Minimize maintenance in harsh conditions

With our optimized laser marking solutions, we have already helped foundries all over the world meet these requirements.