Laser Process Development Service

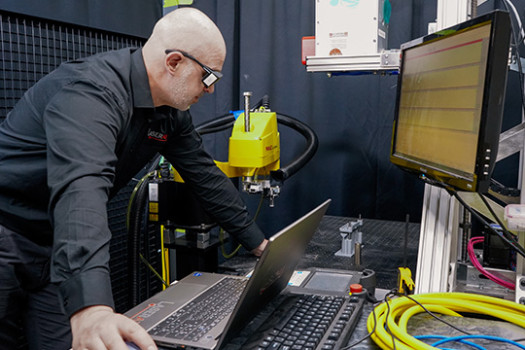

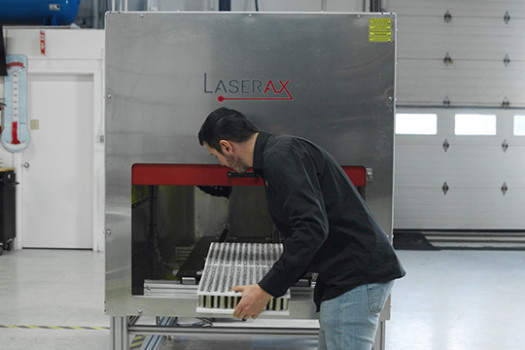

Developing a laser process involves finding the best laser configuration that meets your specific requirements. This includes choosing the right laser, optical components, and parameters.

External factors such as part handling and fume management are also part of developing a laser process, as they can affect quality and efficiency.

Laserax can help you develop a laser process to:

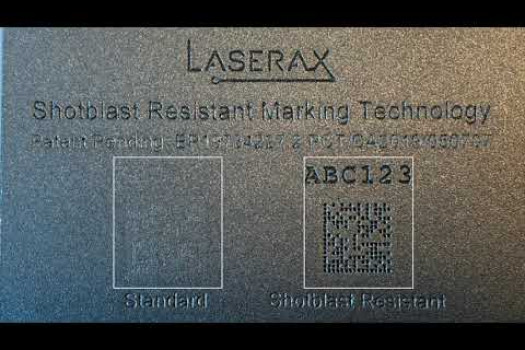

- Replace an existing texturing, cleaning, welding, or marking process with laser technology

- Create a new process to meet specific requirements

- Improve the speed, quality and repeatability of your current process

- Support your product development team

- Optimize the laser process on-site