Types of Laser Marking for Plastics

Color Change (Discoloration)

UV lasers can produce markings by changing the color of the plastic: light colors turn dark through photochemical reactions, while dark colors turn white through photo bleaching.

Foaming

When the laser hits the material, gas bubbles (foam) form within the plastic, which causes the surface to rise and appear whitish. This method is typically used on dark materials to get white marks and can be performed with UV, CO2, fiber, or green lasers. Foaming is only suitable when the change in dimension doesn’t matter.

Carbonization

Marking through carbonization involves heating up the material close to its combustion point. This process requires the presence of carbon in the material, since it is the carbon that turns dark.

Engraving

Engraving is when the fiber, CO2, or UV laser goes deep into the material (UV lasers are slower to engrave than other lasers, due to low power levels) Engraving produces deep & permanent marks that are more resistant to mechanical abrasion, but it does alter the surface of the material and heat & stress can potentially damage the material.

Ablation

Similar to engraving, ablation removes material, but typically on a micron scale, without heating the surrounding surface.

Safety Considerations for Laser Marking

Eyes

Polycarbonate shielding is sufficient for protecting the eyes when using a UV or CO2 laser. Fiber and green lasers, however, require specially coated plastics or glass for eye protection, which are more costly.

Fumes and Particles

Regardless of laser type, fume extraction is always important when marking plastic. In general terms, UV lasers produce the least amount of fumes, fiber lasers produce more, and CO2 lasers produce the most fumes.

Industries that Benefit from Plastic Laser Marking

The versatility of laser marking on plastics makes it a highly effective solution for a wide range of industries:

Automotive

Laser marking is used in the automotive industry to mark essentially any plastic part for identification and traceability. This includes buttons, headlight lamps, wires, electronic components, and more.

Not only does this technique improve production efficiency, but it also ensures companies are compliant with regulatory standards.

Electronics

UV laser marking is particularly useful in the electronics industry because of its ability to label very small components with highly accurate and clear results: microchips, wires, cables, connectors, plastic encapsulated circuits, and other electronic parts.

Medical

Since manufacturers of medical devices are under strict government regulations to ensure the well-being of all patients, the safety and reliability of laser marking makes it a preferred method for the permanent identification of plastic components.

This applies to catheters, catheter hubs, mouthguards, dental appliances, IV bags, tubes, and more.

Packaging

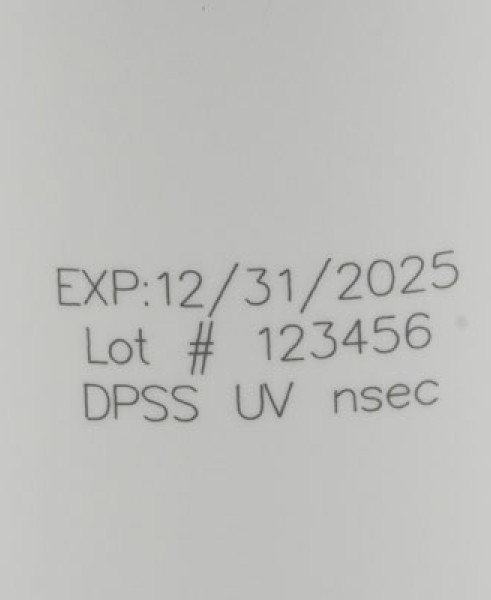

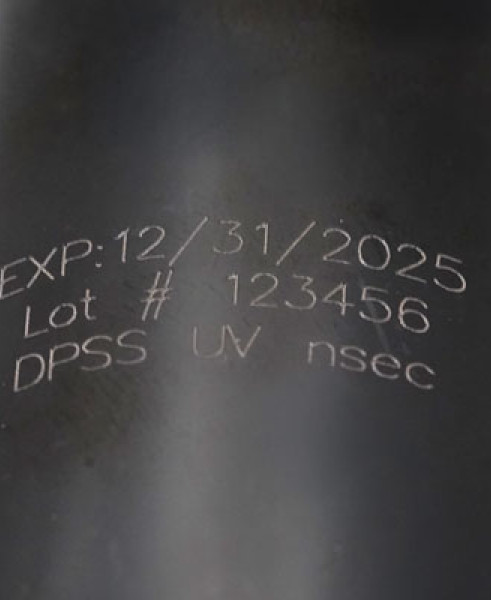

Every packaging material made of plastic that requires branding, traceability, or identification benefits from laser marking technology: plastic bags, containers, clamshells, etc.

Consumer Goods

This can be just about anything: cosmetics, water bottles, toys, USB drives, bottle caps…