Aluminum Extrusion Laser Marking

Aluminum extruders are facing new challenges as more and more programs demand that parts be marked as soon as they're off the press.

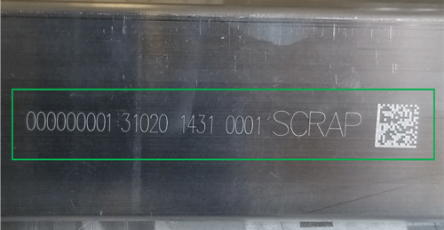

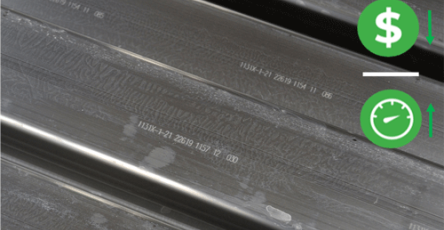

Since inkjet printers are not permanent and hence not suited for automotive programs, an increasing number of extruders are turning to laser marking to permanently etch data matrix codes and serial numbers.