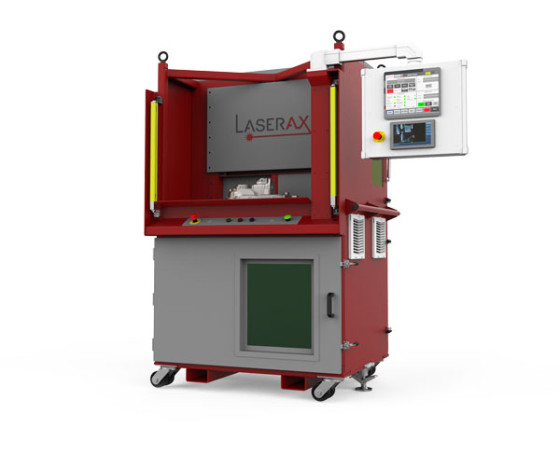

Laser Marking & Workstation Options

Laser Configuration

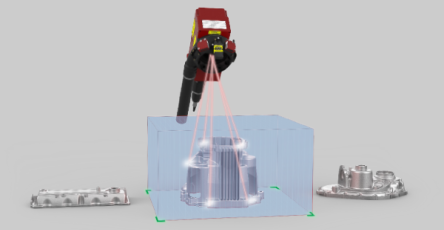

The available laser power ranges from 20W to 500W to speed up the laser marking process as needed, reducing the operator’s waiting time. The workstation can also be configured with a 2D head to mark flat surfaces and compensate for basic imprecisions or a 3D head to be more versatile and support multiple part configurations.

Gantry System

The fiber laser marker can be mounted on a gantry system to operate within a larger marking area and etch multiple parts during the same sequence.

Dust Extraction

A dust extraction system can be installed in the enclosure to automatically extract dust and fumes generated by laser marking. This reduces maintenance and helps keep your workstation environment clean.

Air-Knife

The lens can be protected from dust accumulation by installing air knives on its sides. The continuous airflow contributes to the markings’ consistency and high quality while reducing the laser system’s maintenance.

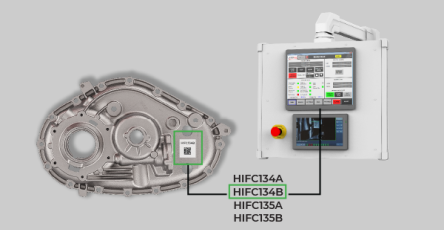

Barcode Validation

Marking quality can be verified directly in the machine with our standard barcode validation system and precalibrated Cognex camera.

Custom Fixtures

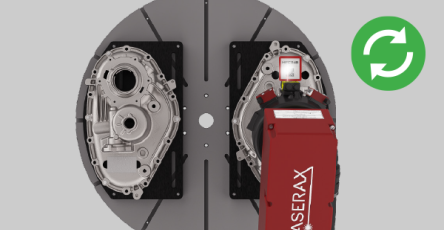

We can provide custom fixtures to fix your parts onto the rotary table.

Fixture Validation

To support operators during changeovers, the workstation can read barcodes on fixtures to automatically detect the part model. In doing so, the operator cannot make mistakes; the right laser marking configuration and automation sequence are always launched.

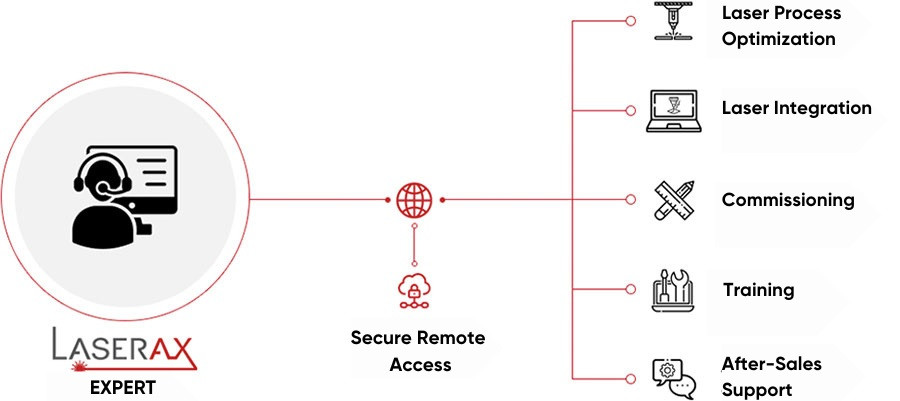

For our complete list of options, contact a Laserax expert.