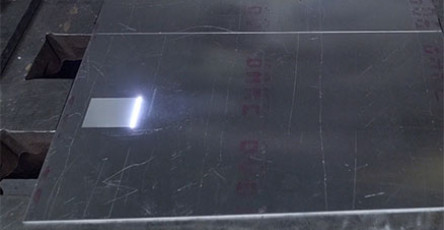

Laser Oxide Removal

Before welding and several other surface treatments, metal surfaces must be clean and without oxides. Laser oxide removal can be used to remove those contaminants without introducing impurities in the base metal. Using the laser’s micron precision, oxide can be removed in controlled layers and from predefined areas.

Fiber laser cleaning systems can remove oxides from ferrous and non-ferrous metals alike. These systems stand out compared to chemical treatments, mechanical brushes and other common methods.