Battery Laser Welding For Battery Pack Manufacturing

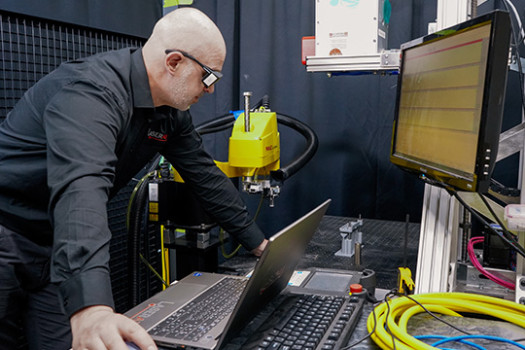

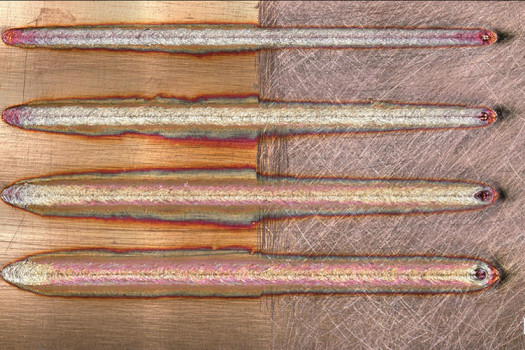

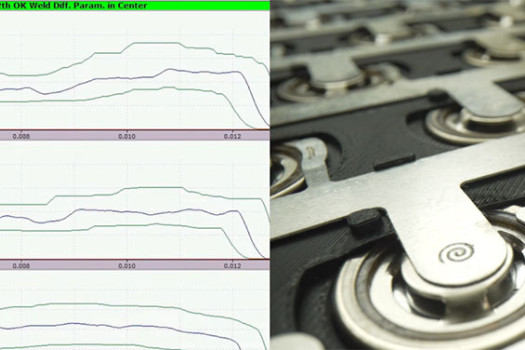

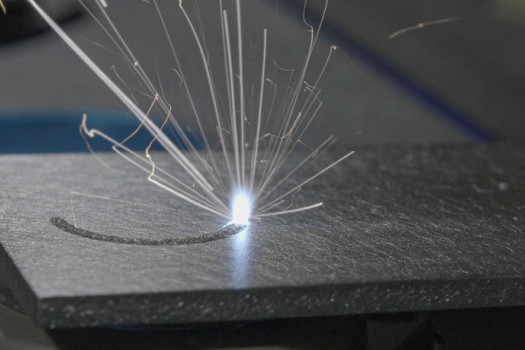

Laser welding is one of the most promising joining technologies for EV batteries and energy storage systems. It provides the speed and precision needed to make the thousands of welds that connect tabs and busbars in battery packs, modules, and cells.

All types of battery cells can be laser welded, including cylindrical cells, prismatic cells, and pouch cells. Laser welding is being implemented for a wide range of electric battery applications:

- Electric vehicles (cars, taxis, etc.)

- Electric commercial vehicles (forklifts, trucks, buses, airplanes, ships, etc.)

- Recreational electric vehicles (motorcycles, bicycles, four wheelers, jet skis, boats, etc.)

- Energy storage systems