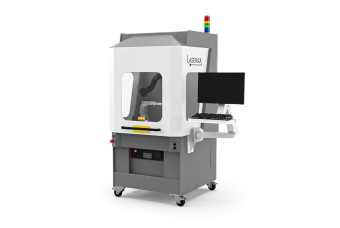

Industrial Laser Marking Machines

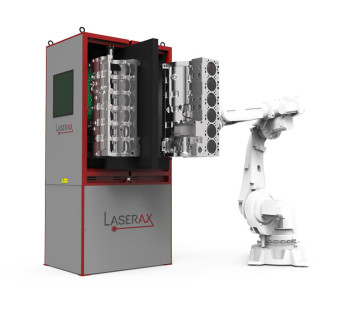

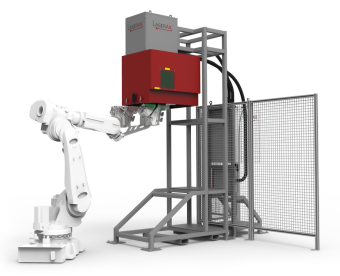

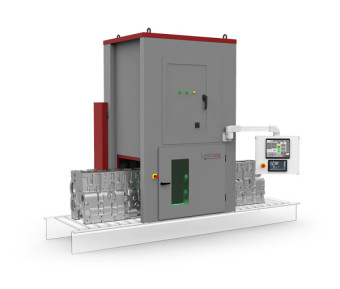

Whether you need a manually loaded workstation or fully automated machine, we offer a wide range of solutions built for industrial applications and optimized to mark metals.

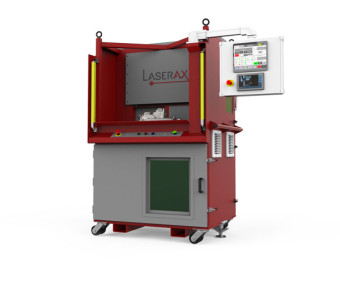

Turnkey laser marking solutions

We offer everything you need to get running, including class-1 laser safety enclosure, active dust and fume management, integrated barcode validation, remote support functionalities, and more.

High-speed lasers

Our laser systems are the fastest every time they are benchmarked. With up to 2,000W of laser power, they can meet any cycle time.

Challenging marking requirements

Our lasers maintain traceability through various post treatments, including shotblasting, e-coating, powder coating, and heat treating. They can also be equipped with autofocus and vision systems to compensate for positioning variations.