Industrial Laser Solutions For The Battery Industry

The world is moving away from fossil fuel dependency, causing a rapid rise in the demand for lithium-ion batteries. Laser technology is a pillar in this transition, helping the battery industry improve its cost-effectiveness, production cycle times, and battery performance. As a green technology, lasers also help lower the environmental footprint.

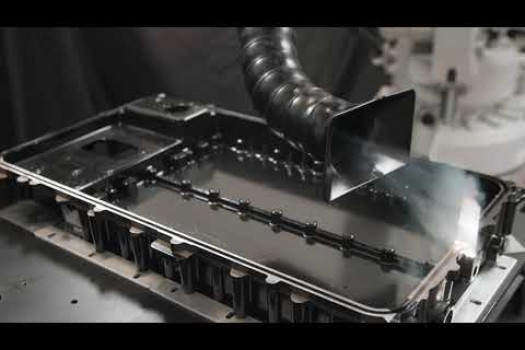

Anyone in the battery industry can benefit from laser technology, whether it’s for electric vehicles, energy storage, or cleantechs. Fiber lasers are used to clean, texture, weld, and mark a wide variety of battery components, such as:

- Cylindrical, pouch and prismatic cells

- Packs and modules

- Tabs and busbars

- Housings, casings, and lids

- Cans and caps

- Foils

- Anodes and cathodes

- And much more...