Battery Laser Marking

There are hundreds of battery cells, modules, and other parts in the battery pack that need to be identified for traceability. Laser marking is an outstanding method to create permanent identifiers at a high speed. Unlike other traditional marking methods, laser marked identifiers can withstand various stresses, such as heat and chemicals (electrolytes, cooling liquids, adhesives, silicones).

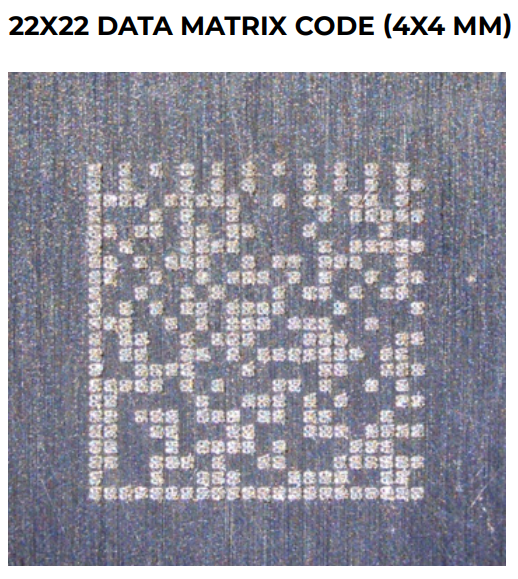

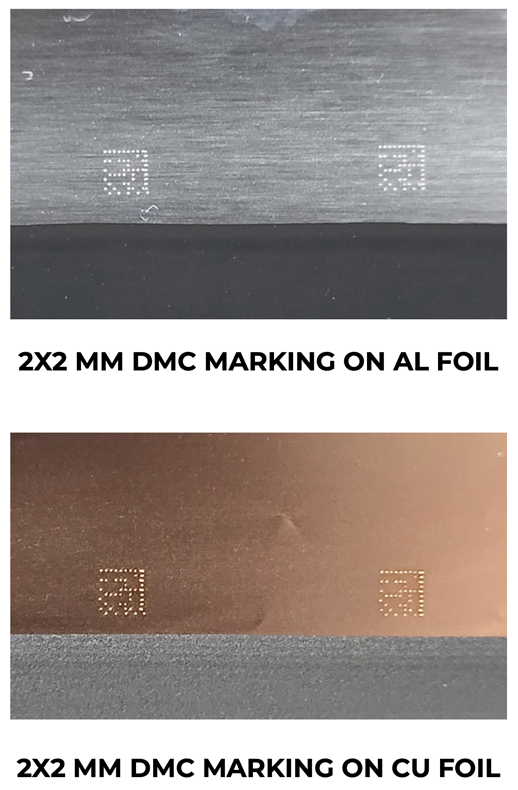

Laser marking can create markings on cells, electrodes, cases, battery modules and packs for individual serial data encoded in machine-readable data matrix codes.