Laser Etching & Engraving

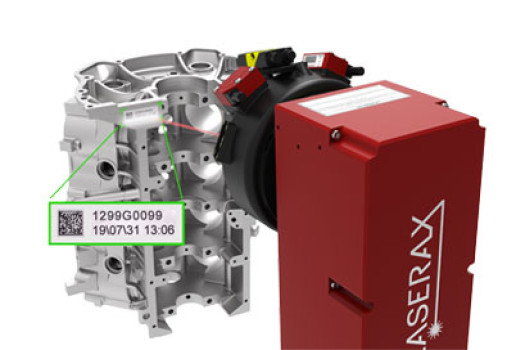

Etching and engraving are the main laser processes used to produce markings onto parts and products. Using a fiber laser system, permanent markings can be etched and engraved onto most metals. The only exception is stainless steel, which requires laser annealing. The most common etchings and engravings are data matrix codes, barcodes, logos, serial numbers and alphanumerical characters.

Unlike alternatives, laser etching and laser engraving systems function without consumables and do not touch the surfaces they mark. For the shop floor, this means low operative costs and low maintenance. These processes are also easy to automate, making them ideal for inline integration. Manufacturers who need batch marking can also operate a workstation.