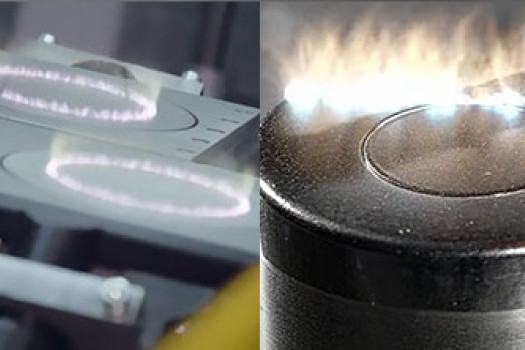

Laser Cleaning Service

With our laser cleaning service, you can send us batches of parts for cleaning. We will remove surface contaminants based on your requirements, then send them back to you or one of your suppliers. If shipping your parts to Laserax is not an option, we can come to you with a laser cleaning machine.

Our service is useful to:

- Validate laser cleaning in your manufacturing process

- Create a small batch for prototyping or preproduction

- Start production while you wait for a laser cleaning machine order

- Accommodate a temporary increase in production