Laser Technology For The Aerospace Industry

The aerospace industry is moving away from fossil fuels. Pushed by the need to electrify transportation, manufacturers of electrified aircraft such as STOLs and eVTOLs are looking for new technologies.

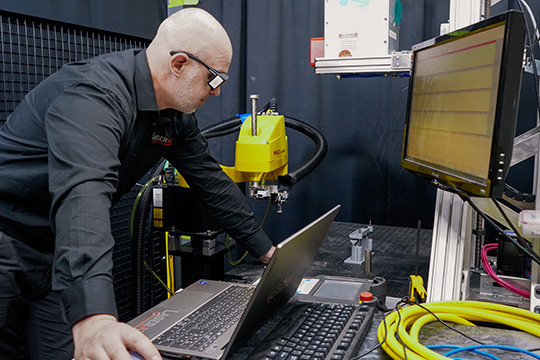

Laser cleaning & texturing can help them automate production, meet safety requirements, and get their products certified.

Laser technology can be used for all types of parts:

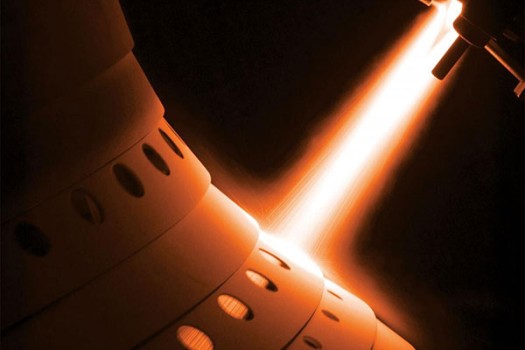

- Electric propulsion engines

- Hydrogen electric engines

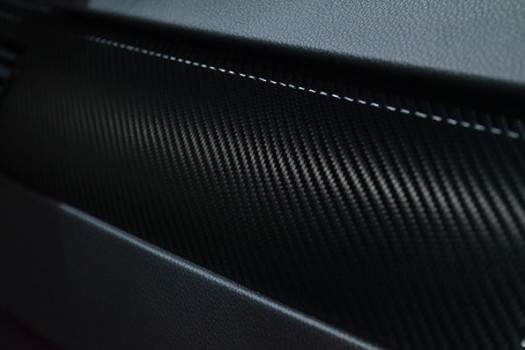

- Battery & e-motor housings

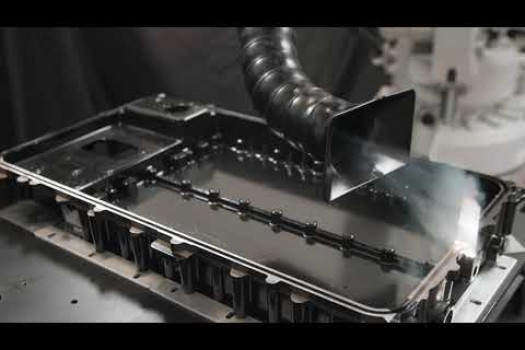

- Cooling plates & tubes

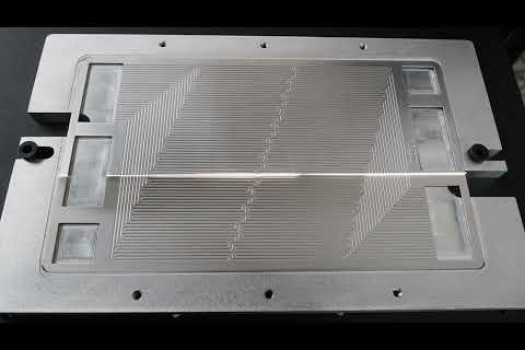

- Metallic bipolar plates

- Battery cells