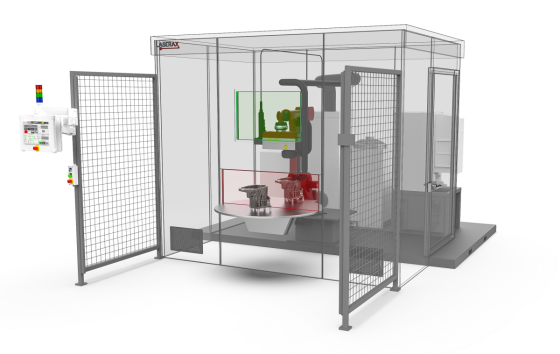

Robotic Arm

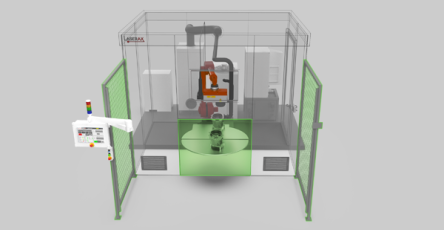

If you want to work with a specific robotic arm, we can adapt the robotic cell to your requirements. The cell can work with robots from major robot supplies such as ABB, FANUC, KUKA, or others.

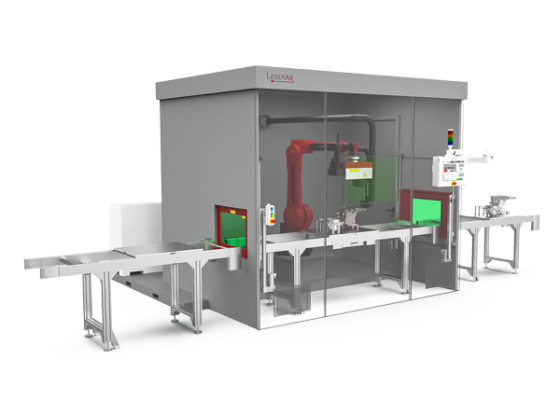

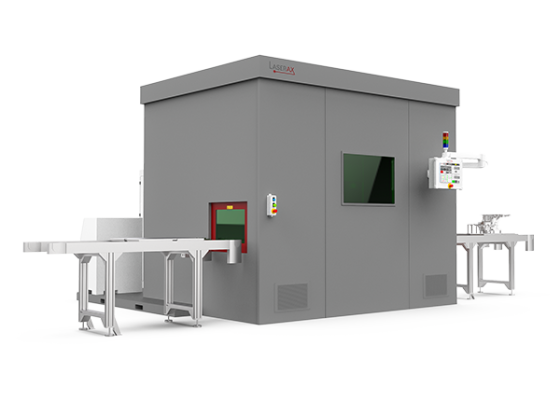

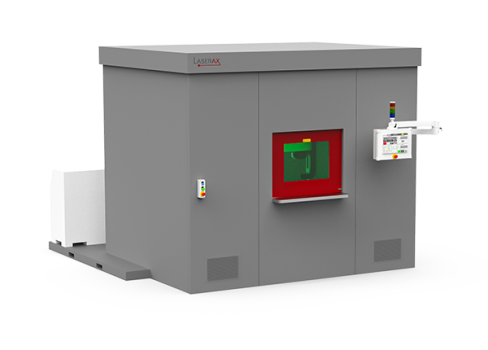

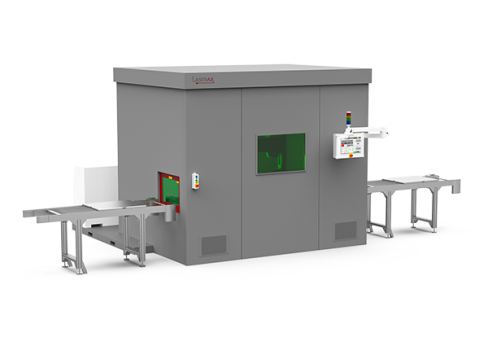

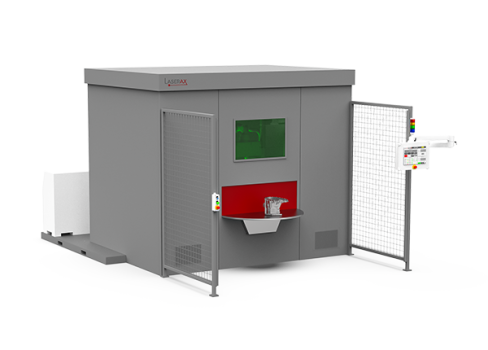

Dimensions

The machine can be customized to fit your production floor. We will work with you to optimize the robot cell’s footprint for your actual production environment, moving its components as needed. For example, the electrical cabinet and control panel can be remotely located to minimize the footprint as well as facilitate operations and maintenance.

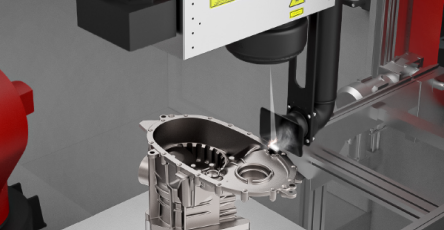

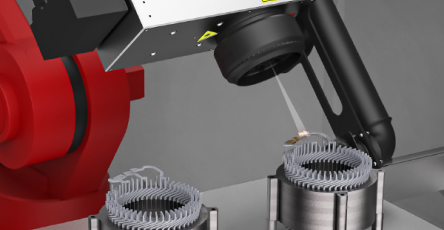

Laser Power

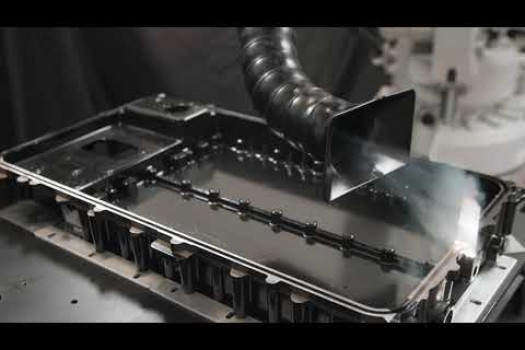

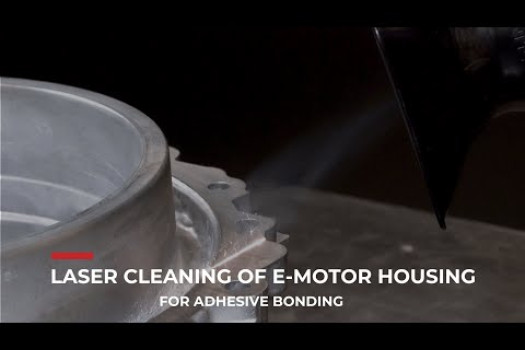

The machine offers a wide range of laser power configurations. A higher power increases the surface treatment speed, allowing you to meet more challenging cycle times.

- Single-mode fiber lasers are available between 20W and 500W. With their smaller spot size, they are ideal for the precise cleaning and texturing of surfaces.

- Multimode fiber lasers are available between 1kW and 3kW. With their larger spot size, they are ideal to clean large areas more effectively.

HMI Control Panel

The standard HMI control panel provides easy access to laser and robot cell parameters:

- Specify a part model to automatically load the corresponding robotic sequence

- Set laser parameters

- Access the manual operation mode to run validation tests or calibrate the laser

- Display information such as the system status and the operation mode

- Access other custom features based on your needs