Laser Machine Options

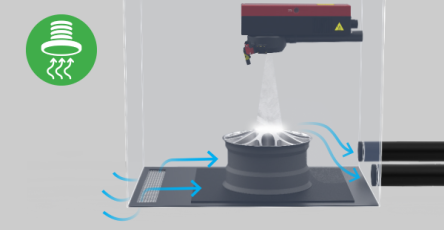

Dynamic Autofocus

Our dynamic, on-the-fly autofocusing system automatically adjusts the laser configuration while the laser head is moved on a gantry system or while the part is moved by a rotary indexer. In doing so, it compensates for positioning imprecisions, resulting in an unmatched cleaning and texturing quality.

HMI Control Panel

The standard HMI control panel provides direct access to laser parameters near the machine. You can:

- Set laser parameters

- Enter the manual operation mode to run validation tests or calibrate the laser

- Display information such as the system status and the operation mode

If you want to add custom features in the HMI, contact us.

Cleaning Quality Validation

Multiple cameras positioned at various angles can validate cleaning results after each operation, making sure the surface is sufficiently cleaned based on your requirements.

Laser Configuration

The machine is powered by a fiber laser whose power can range from 20W to 500W. A higher power increases the surface treatment speed, allowing you to meet more challenging cycle times.

We also offer two types of laser heads. 2D heads are typically used for surface treatments on flat surfaces. 3D heads can be used to treat any types of surface geometries, including curved ones, or to treat surfaces at different heights without moving the head.

Custom Fixtures

Our team can build custom fixtures to fix your parts into position.

Fixture Validation

Leave no room for operation mistakes that lead to poor surface treatment performance. Our fixture validation system can automatically read the fixture’s barcode and load its corresponding parameters. As a result, the right laser configuration and automation sequence are started every time.

Automation Features

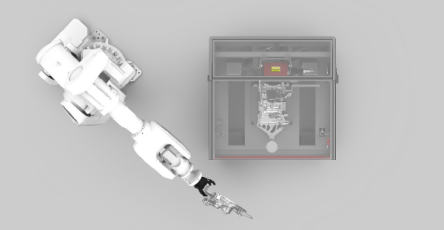

Gantry System

The laser head can be mounted on a gantry system to move it along three linear axes. This allows you to clean and texture larger surfaces as well as several areas with a single laser head.

Automatic Drawer

Located outside the machine, the automatic drawer makes part loading easier for robots or operators by automatically moving parts inside the machine. With simplified machine access, you also gain in flexibility when optimizing your plant layout.

Rotary Indexer

If you need to clean or texture a part at different angles (such as when cleaning a part’s circumference), a rotary indexer can be used to fix the part and automatically rotate it.

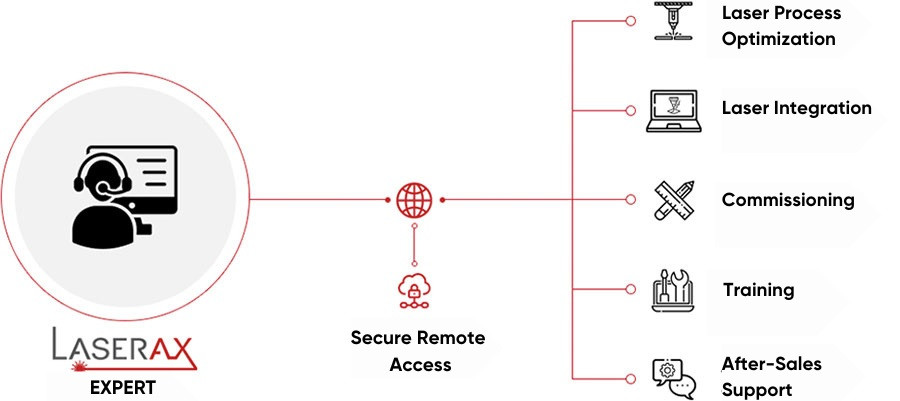

For more machine options, contact a Laserax expert.