Laser Workstation Options

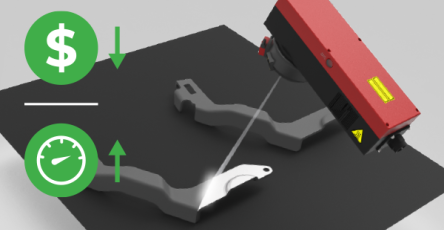

Laser Configuration

The workstation is powered by a fiber laser whose power can range from 20W to 100W. Higher power increases the cleaning speed and reduces your operator’s waiting time.

Our basic configuration includes a 2D laser head. However, a 3D laser head can be used to clean and texture with more flexibility. For example, it is used for curved shapes, or when you need to clean several parts during the same laser cleaning sequence without moving the head.

Dust & Fume Extraction

Texturing and cleaning generate dust and fumes. For this reason, we offer different models so you can use the extraction power that meets your needs.

Air Knife

Air knives installed on the lens prevent dust from accumulating on the lens by blowing a continuous airstream. Not only does this reduce lens cleaning maintenance, but it also helps you obtain more consistent results.

Automation Features

Motorized Door

The workstation has a large door that can be motorized to make manual tasks easier and thus increase the operator’s productivity. If you want to automate the workstation, you also need this feature.

The motorized door has pressure-sensitive safety edges, but you can also add our optional light curtain to meet advanced safety requirements.

Z-axis Head Adjustments

The laser head’s Z-axis needs to be adjusted before cleaning or texturing parts at different heights. The first solution is to make manual or motorized adjustments with guidance from our laser pointer, which indicates the correct position for the laser head. However, you can also choose automatic adjustments that are launched by choosing a preprogrammed position in our touchscreen HMI.

Rotary Indexer

If you need to clean or texture apart at different angles (such as when cleaning a part’s circumference), a rotary indexer can be used to fix the part and automatically rotate it.

Touchscreen HMI

The touchscreen HMI can be used to easily choose the right laser process when cleaning or texturing different parts and materials. It can also be used to control other automation features and avoid manual laser head adjustments.

Cleaning Quality Validation

Multiple cameras positioned at various angles can validate cleaning results after each operation, making sure the surface is sufficiently cleaned based on your requirements.

Custom Fixtures

Our team can build custom fixtures to fix your parts into position in the workstation.

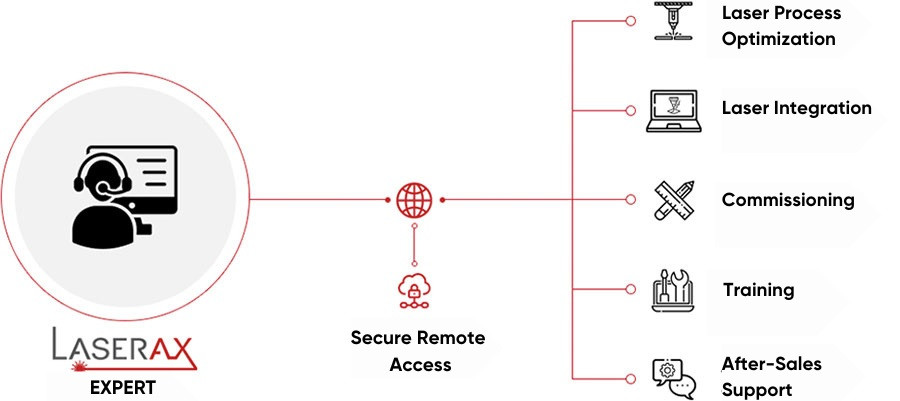

For more workstation options, contact a Laserax expert.