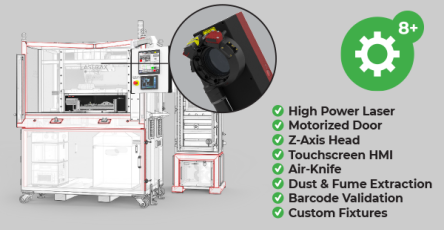

Laser Workstation Options

Laser Configuration

The workstation is powered by a fiber laser whose power can range from 20W to 500W. A higher power increases the surface treatment speed and reduces your operator’s waiting time.

We also offer two types of laser heads. 2D heads are typically used for surface treatments on flat surfaces while 3D heads can be used to treat any types of surface geometries, including curved ones.

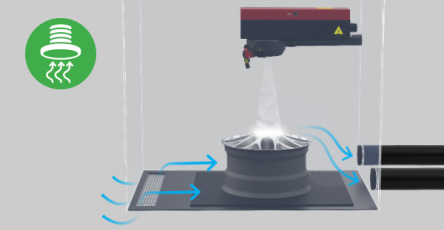

Dust & Fume Extraction

Choosing the right power for your dust and fume extraction unit is extremely important to ensure the safety of its operators and the constant quality of the laser process. For this reason, we offer different models so you can select the right one for your fume extraction requirements.

Air Knife

Air knives installed on the lens prevent dust from accumulating on it by blowing a continuous airstream. Not only does this reduce lens cleaning maintenance, but it also helps you obtain more consistent results by keeping the laser beam unobstructed.

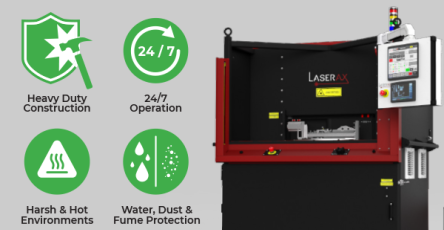

Automation Features

Gantry System

The laser head can be mounted on a gantry system to clean or texture a larger area and to process multiple areas on a part, and this, within the same sequence.

Rotary Indexer

If you need to clean or texture a part at different angles (such as when cleaning a part’s circumference), a rotary indexer can be used to fix the part and automatically rotate it.

Cleaning Quality Validation

Multiple cameras positioned at various angles can validate cleaning results after each operation, making sure the surface is sufficiently cleaned based on your requirements.

Custom Fixtures

Our team can build custom fixtures to fix your parts into position onto the rotary table.

Fixture Validation

Leave no room for operation mistakes that lead to poor surface treatment performance. Our fixture validation system can automatically read the fixture’s barcode and load its corresponding parameters. As a result, the right laser configuration and automation sequence are started every time.

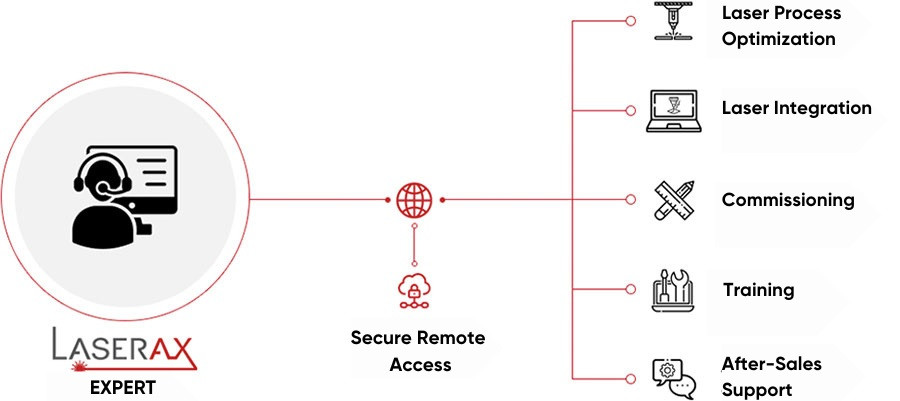

For more workstations options, contact a Laserax expert.