Laser Rust Removal

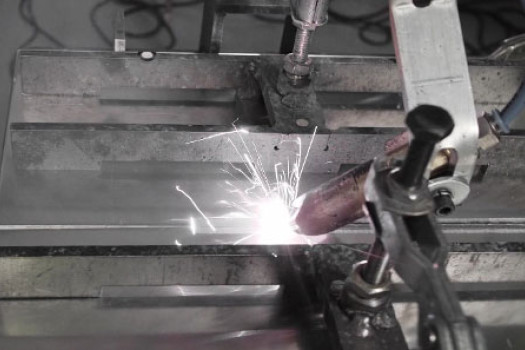

Fiber laser cleaning can remove rust and other corrosion-inhibiting agents. It is often used as a pre-treatment for welding or coating.

In automotive, aerospace, and more general industrial applications, the potential of fiber laser technology is still unknown. This revolutionary cleaning technique makes it possible to clean surfaces without the need for consumables, chemicals, or masking. It’s also a cost-effective alternative to traditional cleaning methods like sandblasting, wheel blasting and chemical cleaning.

Laser cleaning can remove rust, oxides, paints, coats, electrolytes, and other contaminants from metal surfaces. Emerging applications include weld cleaning, mold cleaning, tool cleaning, and surface preparation for adhesive bonding.

With its high precision, laser cleaning can clean specific areas without affecting surrounding ones. Selective laser cleaning is most useful to prepare surfaces for welding or assembly. It is often used to get rid of masking, a tedious process that’s prone to error.

Pulsed laser beams remove contaminants with unprecedented consistency, and this, without introducing impurities or damaging the base material.

This is a big improvement compared to abrasive methods like media blasting and brushes. These methods can damage surfaces—especially soft or thin ones. They also tend to generate inconsistent results, as they quickly deteriorate.

Because no dangerous products are involved (such as chemical solvents or abrasive media), laser cleaning systems don’t need to be installed in a dedicated room where employees wear personal protective equipment.

To achieve complete safety, the laser only needs to be installed in a Class-1 laser safety enclosure and equipped with a fume extraction system.

Chemicals and blast particles add up to a significant amount of waste. Lasers generate none, which reduces the environmental risks related to contamination and pollution.

Because it’s a non-contact process and no consumables need to be replaced, laser cleaning requires little maintenance. As a result, maintenance costs are low and consumables costs nonexistent. The low amount of dust generated also facilitates automation and quality control in production lines.

Fiber laser cleaning can remove rust and other corrosion-inhibiting agents. It is often used as a pre-treatment for welding or coating.

This process is used to clean metal surfaces before surface treatments, especially before aluminum welding. It is also used after welding to remove stainless steel oxides.

Also known as laser coating removal, this method vaporizes paint while leaving the underlying surface intact. It is used to replace part masking, clean painting tools, prepare welding areas, salvage parts with paint defects, and more.

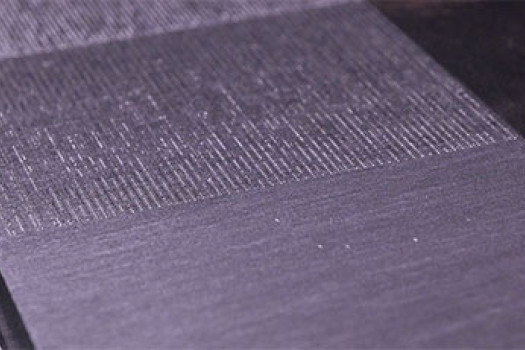

Laser surface cleaning can prepare parts for adhesive bonding, making sure no oxides interfere with the bonding process. When needed, the laser can also roughen the surface to promote mechanical interlocking.

Lasers can clean surfaces while leaving a slight texture that improves adhesion. This is useful if you need to prepare surfaces for a subsequent process, such as bonding or painting.

Our experts share their laser cleaning results before and after welding. You can see an innovative integration in an automated welding cell, learn the benefits of laser cleaning before and after welding, and find out laser cleaning speeds.

Using a high-power fiber laser, our experts compare the speed at which rust, paint, dust, oil and mill scale are removed at different power levels.

Laser cleaning is explained in five simple steps. Key concepts are covered to explain how material is removed, including laser ablation, pulsed laser beams, and energy levels.

Receive monthly updates and latest news.

© 2026 Laserax ®. All Rights Reserved.