How to Validate Laser Cleaning Quality

Laserax uses a range of standard, proven tests to ensure that the cleaned surface is free of any coatings or organic contaminants. First, the metal’s wettability is measured with a water contact angle (WCA) test.

Water Contact Angle

By measuring the contact angle on the cleaned surface with a surface analysis device, we can see if any contaminants prevent water from spreading. A lower contact angle (around 10 degrees) indicates a clean metal surface.

Reflective Fluorescence Units

Cleanliness is also measured with Relative Fluorescence Units (RFU). RFU values are registered by a fluorescence measurement device which irradiates UV rays on the metal surface and quantify the resulting fluorescence from the contaminants.

Just as we measure noise to quantifies silence, we measure the fluorescence of contaminants to measure cleanliness. The lower the RFU value, the cleaner the metal.

Single-Mode vs. Multi-Mode Lasers

Single-mode lasers convey laser light more efficiently and have a better beam quality in comparison to wider, more powerful multi-mode lasers. Both laser types can be used to remove contaminants for metal surfaces.

The main differences are that single-mode lasers can etch a surface texture during cleaning to improve adhesion whereas multi-mode lasers can clean surfaces faster.

CLEANING SPEEDS FOR COATING REMOVAL

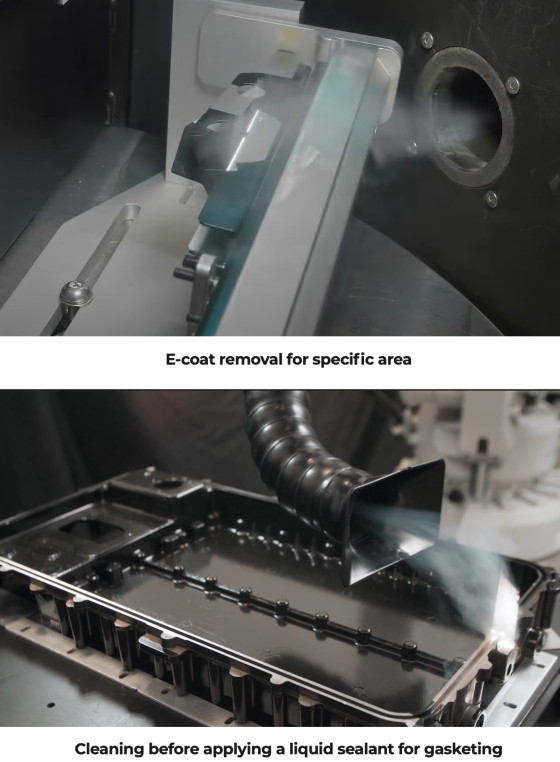

Laser cleaning removes coating layers from metal surfaces without damaging the substrate. Laserax achieved the speed results below in multiple projects . Requirements included achieving WCA values of <= 10° and RFU values of <= 10. Coating removal was tested for different thickness levels on coatings such as:

- Powder coating

- Phosphate coating

- E-coating (KTL, Cataphoresis)

| | SINGLE-MODE [in2/s] | MULTI-MODE [in2/s] |

|---|

| Material | Description | 100W | 200W | 300W | 500W | 1kW | 2kW | 3kW |

|---|

| E-coating & Phosphate coating | 25μm | 0.1 - 0.2 | 0.2 - 0.3 | 0.3 - 0.4 | 0.5 - 0.6 | 0.6 - 1.2 | 1.1 - 2.4 | 2.4 - 3.5 |

|---|

| 50μm | 0.08 - 0.1 | 0.1 - 0.2 | 0.1 - 0.2 | 0.2 - 0.3 | 0.3 - 0.6 | 0.5 - 1.2 | 1.2 - 1.7 |

| Paint & Powder coating | 100μm | 0.03 - 0.1 | 0.1 - 0.2 | 0.2 - 0.3 | 0.3 - 0.4 | 0.5 - 1.2 | 1.9 - 3.6 | 3.9 - 5.1 |

|---|

| 200μm | 0.01 - 0.05 | 0.05 - 0.07 | 0.08 - 0.1 | 0.1 - 0.2 | 0.4 - 0.6 | 1.3 - 1.7 | 2.0 - 2.6 |

| Epoxy | 0.5mm | 0.02 | 0.03 | 0.06 | 0.09 | 0.12 | 0.17 | 0.19 |

|---|

CLEANING SPEEDS FOR OTHER MATERIALS & CONTAMINANTS

Laser cleaning is an effective method for cleaning metal surfaces of contaminants that have accumulated during production. Laserax achieved the results below in multiple projects with different requirements.

| | SINGLE-MODE [in2/s] | MULTI-MODE [in2/s] |

|---|

| Material | Requirements | 100W | 200W | 300W | 500W | 1kW | 2kW | 3kW |

|---|

| Oil | Esthetic Finish | 0.9 - 1.4 | 1.6 - 2.2 | 2.0 - 2.6 | 2.6 - 3.0 | 18.6 - 32.7 | 39.4 - 63.2 | 62.3 - 91.1 |

|---|

| WCA = 30‑40 | 0.6 - 0.7 | 1.0 - 1.3 | 1.3 - 1.8 | 1.7 - 2.5 | 7.0 - 10.8 | 17.5 - 32.0 | 30.4 - 43.4 |

| WCA = 10‑20 | 0.4 - 0.6 | 0.7 - 0.9 | 0.9 - 1.3 | 1.3 - 1.6 | 1.2 - 3.3 | 5.4 - 10.2 | 9.8 - 17.0 |

| Oxide | Esthetic Finish | 0.8 - 1.0 | 1.8 - 2.0 | 2.5 - 2.9 | 3.6 - 5.5 | 18.6 - 32.7 | 39.4 - 63.2 | 62.3 - 91.1 |

|---|

| WCA = 30‑40 | 0.5 - 0.7 | 0.7 - 1.1 | 1.1 - 1.5 | 1.7 - 2.3 | 5.3 - 8.5 | 15.5 - 23.3 | 21.7 - 32.6 |

| WCA = 10‑20 | 0.3 - 0.5 | 0.6 - 0.9 | 0.9 - 1.3 | 1.3 - 1.6 | 1.7 - 3.9 | 5.3 - 9.6 | 10.0 - 14.5 |

| Rust | Grade C | 0.1 - 0.6 | 0.3 - 1.6 | 0.5 - 1.9 | 0.8 - 2.3 | | | |

|---|

| Mill Scale | General | 0.01 - 0.09 | 0.03 - 0.2 | 0.05 - 0.3 | 0.08 - 0.5 | | | |

|---|