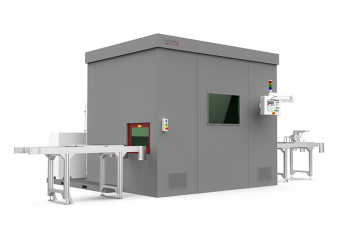

Manual & Automated Laser Cleaning Machines

Our laser cleaning machines range from manually loaded to fully automated solutions to meet the needs of various applications. The world’s best manufacturers rely on our solutions and expertise to scale up their production and ensure quality.

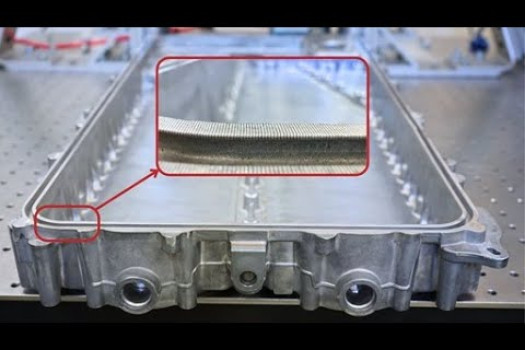

Laser cleaning & surface preparation

Remove coatings, paints, oxides, rust, and any types of contaminants from metal surfaces. Modify the surface texture and chemical composition to improve adhesion.

Industrial grade lasers

Keep up with cycle time requirements with a high-power laser cleaning system (up to 3kW). Minimize downtime with high-quality components, including a fiber laser source that can continuously operate for +10 years with minimal maintenance.

Turnkey laser cleaning solutions

Get all the features you need from a single supplier, including automation, laser process development, fume management, laser safety, on-site & remote support, and performance optimization.

Trusted by...