Laser Machine Options

Laser Power

The machine is powered by a fiber laser whose power can range from 20W to 500W. A higher power increases the surface treatment speed, allowing you to meet more challenging cycle times.

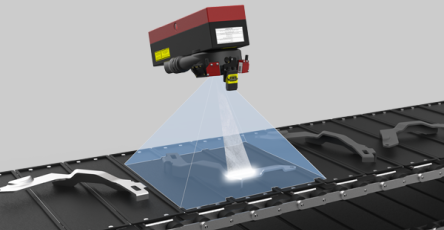

Dynamic Autofocus

Our on-the-fly autofocusing system allows you to clean and texture parts of various shapes and sizes while they are moving on the conveyor, and this, without slowing it down.

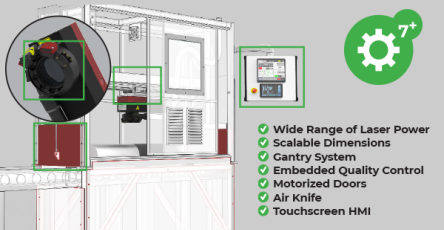

Gantry System

The laser head can be mounted on a gantry system to move it along three linear axes. This allows you to clean and texture larger surfaces as well as several areas with a single laser head.

X-Y Vision System

The vision system locates parts that are beyond the laser’s field of view when part positioning variations are too high on the conveyor. The laser head is then moved to the right location (using a gantry system) to perform the surface treatment.

HMI Control Panel

The standard HMI control panel provides direct access to laser parameters near the machine. You can:

- Set laser parameters

- Enter the manual operation mode to run validation tests or calibrate the laser

- Display information such as the system status and the operation mode

If you want to add custom features in the HMI, contact us.

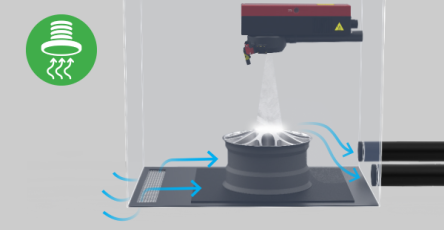

Cleaning Quality Validation

Multiple cameras positioned at various angles can validate cleaning results after each operation, making sure the surface is sufficiently cleaned based on your requirements.

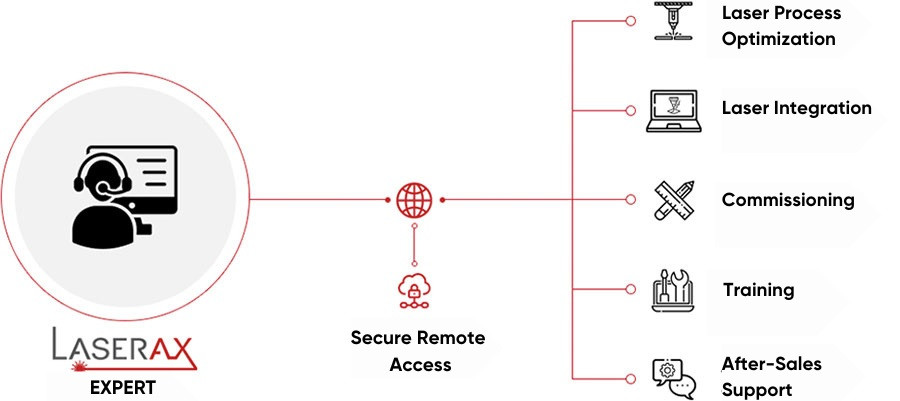

For more machine options, contact a Laserax expert.