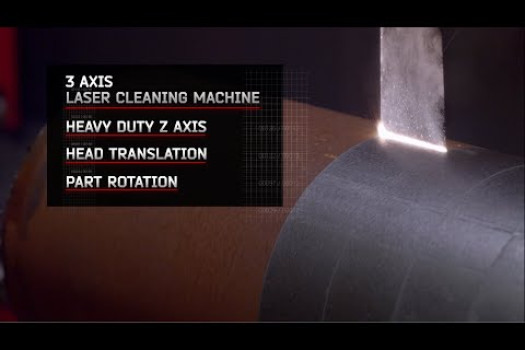

Laser Machine Options

Laser Power

The LXQ-HP offers between 200W and 500W of laser power for high-speed applications.

Laser Head

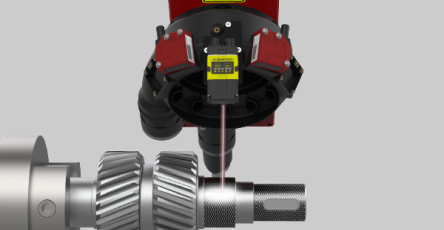

2D heads can easily compensate for surface roughness imprecisions on flat surfaces. They set a high standard with a depth of focus of 6 mm, which prevents complex laser head adjustments.

3D heads add the focusing range needed to process any types of geometries and compensate for bended parts. They can also be positioned at a 45° angle.

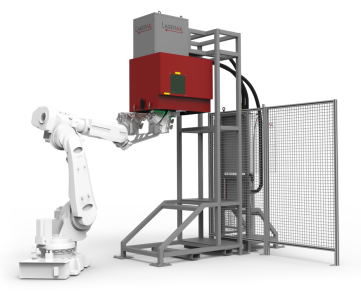

With up to 8m of fiber cable length, our heads can easily be mounted on robots, gantry systems and so on, allowing you to work over a large area if needed. They are also certified IP-67, offering advanced protection against dust and liquids.

Lens Configuration

The standard lens configuration is optimal for most applications. Not only does it offer a huge working field, but the lens is at a good distance from the part to prevent the dust generated by the laser process from accumulating on the lens.

The advanced lens configuration is used for applications that require deep engravings. For example, some laser texturing applications require a high roughness. Some laser marking applications also need 2D codes that maintain traceability after shotblasting.

Standard Accessories

The air-knife is installed on the lens, blowing a continuous airstream that protects it against dust accumulation. The lens needs to be cleaned less often and you obtain results that are much more consistent.

Our optional Class-1 enclosures offer you a quick way to guarantee laser safety.

The HMI control panel provides direct access to laser marking parameters. You can:

- Manually adjust the laser marking zone, scale the identifiers, edit them and more

- Enter the manual operation mode to run tests or calibrate the laser

- Display information such as the system status, the operation mode and the alarm history

Advanced Features

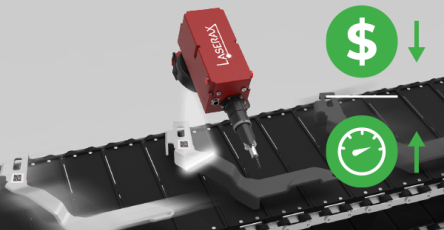

Our dynamic autofocus system allows you to clean moving parts of various shapes and sizes (on-the-fly technology). Parts are cleaned with unmatched precision and at the speed of your manufacturing process. .

Our 3D Autofocus system identifies variations in the part’s positioning and adjusts the laser accordingly to repeatedly generate optimal results. This feature can save you time and reduce the cost of your solutions by removing the need for complex laser head adjustments.

Our barcode validation feature includes a precalibrated Cognex camera and a validation system. You can validate code quality just after laser marking, and algorithms can predict which codes will meet your marking requirements if there are post treatments like shotblasting and e-coating.

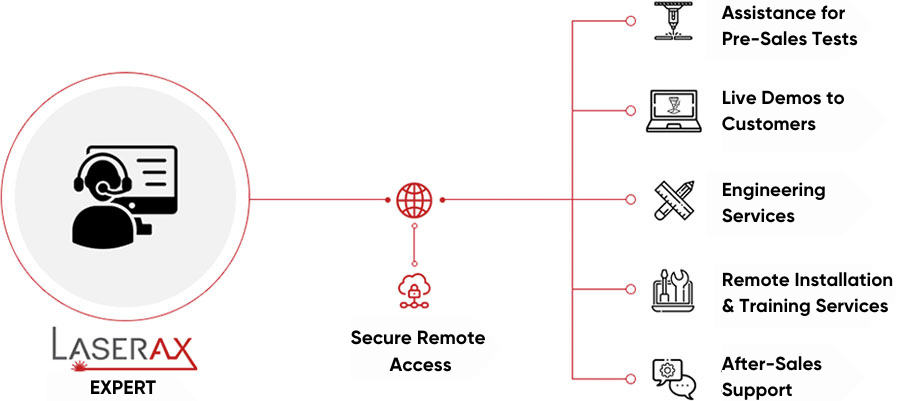

Advanced features are configured by the Laserax team so that they’re ready to be used. During integration, you simply need to connect them on the controller’s back panel.

For our complete list of features and options, contact a Laserax expert.