LASER TECHNOLOGY FOR THE MEDICAL Industry

Precision, cleanliness and reliability are crucial in medical device manufacturing. In line with these requirements, laser technology provides unmatched accuracy and repeatability.

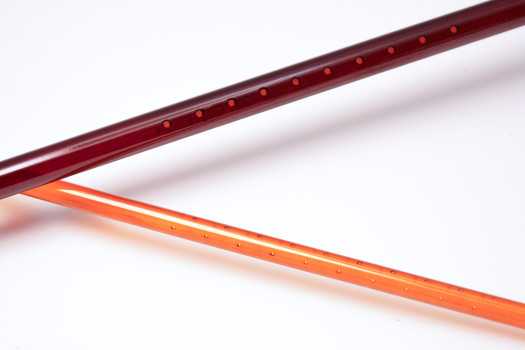

Laser solutions can deliver high-speed, non-contact processes for multiple coding/marking, micro-drilling, and surface texturing applications.

Laser technology is used for various medical devices, including:

- Dental aligners, implants and retainers

- Polymer and stainless-steel tubing

- Metal dental/medical tools

- Catheters and wires

- Eyeglass lenses