Laser Welding Service

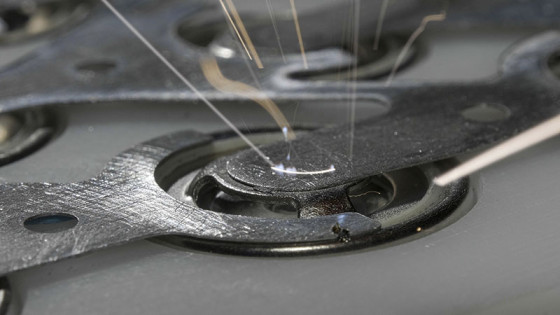

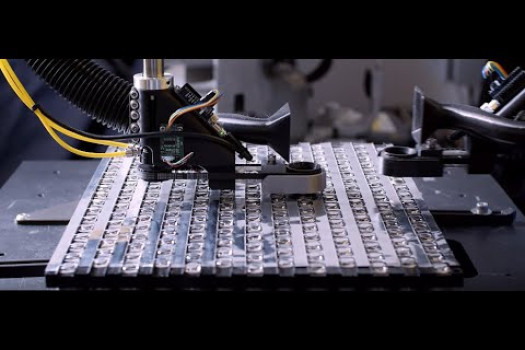

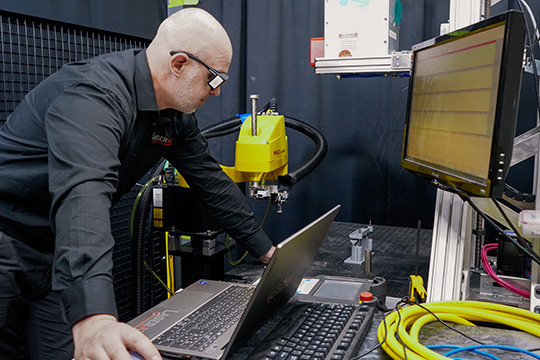

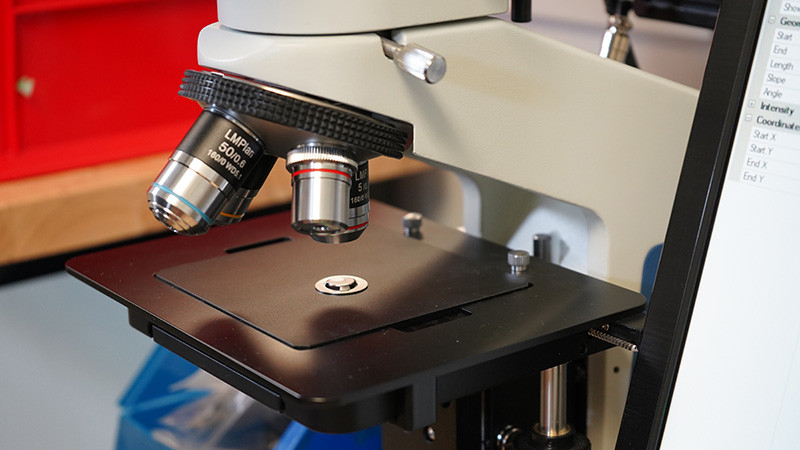

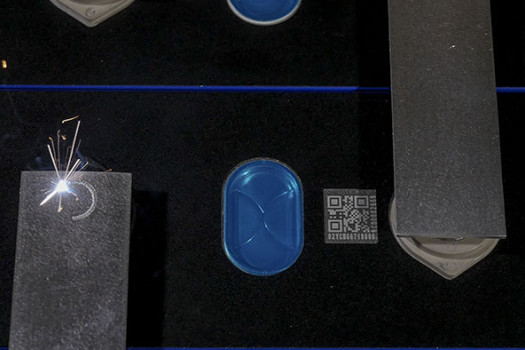

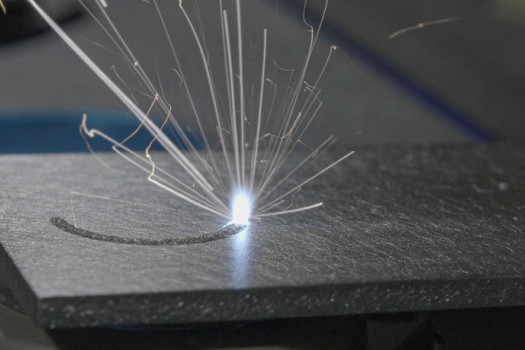

Our laser welding service allows you to send us small batches of parts for welding. We will develop a laser welding process for you and test the laser process on coupons and samples to make sure it meets your specifications. Then, we will weld your parts.

With this service, you can:

- Validate laser welding in your manufacturing process

- Produce a small batch for prototyping or preproduction

- Meet a short-term surge in production.

- Start producing right away while waiting for a laser welding machine order