This case study is based on real applications developed for a Tier 1 automotive supplier. For confidentiality reasons, specific names and details of the manufacturing process cannot be disclosed.

Achieving Superior Bonding & Surface Cleaning with a 2-in-1 Laser Solution

A world-leading Tier 1 OEM in the automotive industry sought to optimize the manufacturing process of powertrain and structural components by enhancing the surface preparation step for those critical metal parts.

The client needed a reliable and automated solution to improve adhesion for bonding applications and efficiently remove contaminants without damaging the underlying material. Multiple parts required surface texturing to ensure consistent adhesive bonding strength and cleaning to remove surface contaminants.

However, the components either have complex geometry, a large surface or multiple surfaces to be treated. Their existing mechanical and chemical surface treatment methods were also inconsistent, labor-intensive, and costly.

To maintain high production standards, they required a fast, automated and repeatable surface preparation solution that would increase efficiency, reduce rework, and seamlessly integrate into their workflow.

Objectives

Integrating Laserax’s laser cleaning and texturing technology into the client’s manufacturing process aimed to ensure two outcomes:

- Precise surface contaminant removal of oils, oxides and particulate matter from electric motors components such as motor housings and gaskets.

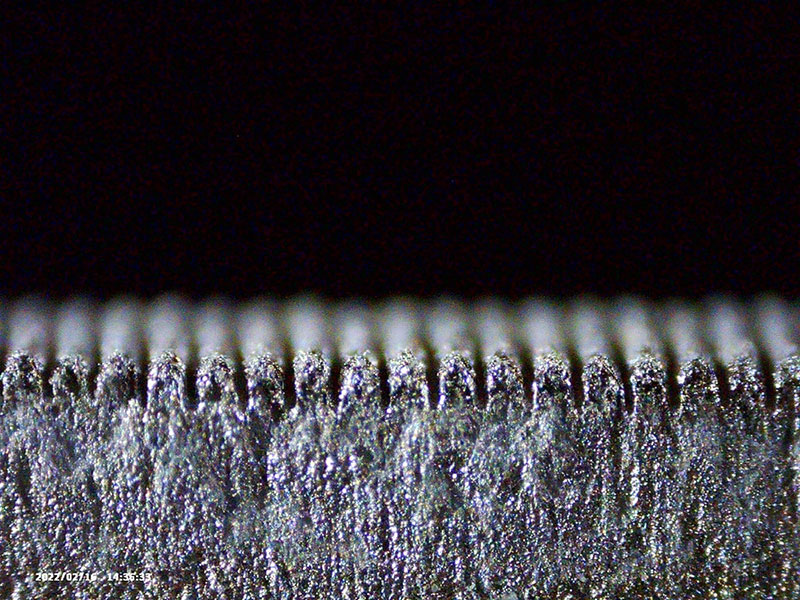

- Consistent adhesive bonding strength of challenging components with high-quality surface texturing.

The laser solution had to be scalable, automated, and aligned with the client's sustainability goals to replace the previously used surface treatment methods successfully.

Switching to Laserax’s solution was a game-changer. We now achieve flawless bonding without the hassle of consumables or inconsistent treatments. Its automation and precision not only boosted efficiency but also cut costs and waste. It’s a reliable, automated solution that seamlessly fits into our high-volume production. – Process Engineering Manager

Solution

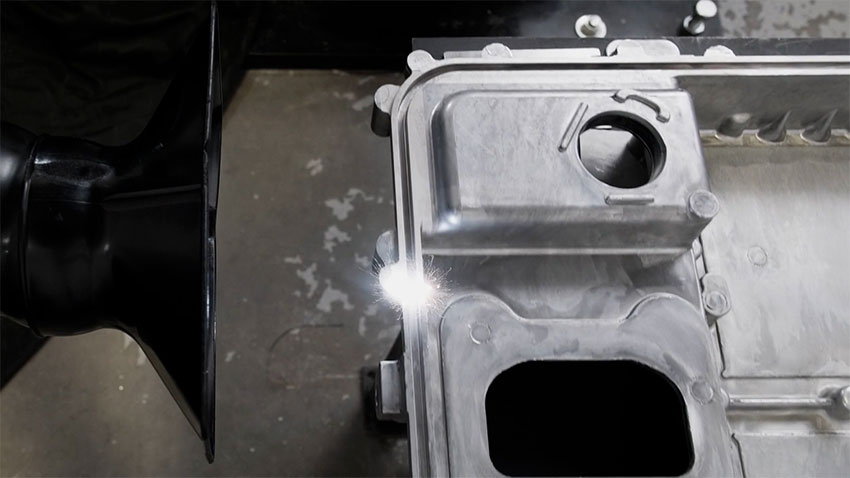

To solve this double challenge, Laserax provided a custom, high-power 300W robot laser cleaning machine designed for automated integration with a 6-axis robotic arm.

This technology effectively removed contaminants and eliminated the need for masking, consumables and secondary cleaning steps. Moreover, its camera-based vision alignment ensured precise and repeatable surface texturing of multiple parts with complex shapes and large or multiple surfaces.

Laserax's 2-in-1 laser process allowed optimal and repeatable bonding conditions while protecting the parts’ integrity, thanks to a fume extraction nozzle installed on the robot arm. Laserax’s engineering team also assisted the client with installation and Class-1 laser safety certification.

Output

The client optimized their surface preparation process by implementing Laserax’s automated laser cleaning and texturing technology, producing high-quality components with consistent adhesion and bonding reliability. The transition to laser technology cut production costs, increased efficiency and eliminated rework.

Following this success, the client has expanded laser integration across multiple production lines, reinforcing their trust in Laserax’s expertise in advanced laser solutions.

Benefits of Our Solution

- Precise cleaning

The laser machine selectively removed oils, oxides and particulate matter without damaging the parts and components. - Consistent surface preparation

The same laser machine delivered consistent, defect-free surface preparation to meet the client’s bonding requirements despite complex shapes and multiple surfaces. - Non-contact & green solution

Our durable solution replaced outdated methods requiring consumables, chemicals, high energy and maintenance, reducing costs and environmental impacts. - Fast & repeatable process

The integrated 6-axis robot arm increased process repeatability and bonding reliability by providing a highly controlled texture while maintaining high-speed cycle times. - Seamless integration

Our automated laser solution was installed with minimal disruption and is easily scalable for our client’s future production lines.

Manufacturing Improvements

- Superior bonding & cleaning conditions

Bonding failures and decontamination inconsistencies dropped dramatically, increasing the overall yield. - Streamlined process

The previous methods required additional rinsing, drying, refinishing and manual labor steps, which are no longer necessary. - Optimized throughput

The automated system ensured consistent cycle times and reduced downtime with optimal floor space. - Cost savings and sustainability

Eliminated reliance on masking, abrasives and chemicals, reduced energy consumption and maintenance, and increased process lifespan.