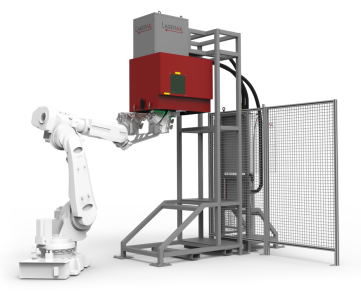

ALUMINUM LASER MARKING AND ENGRAVING

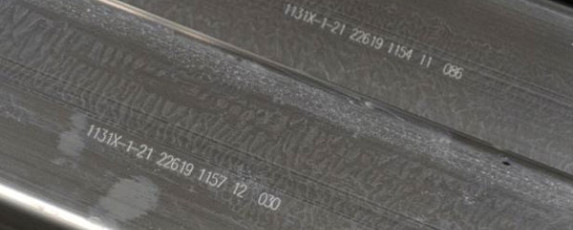

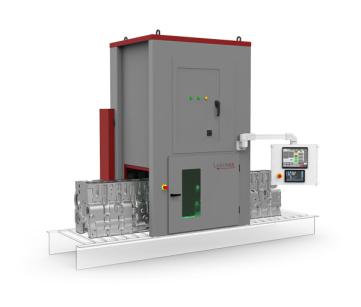

For marking and traceability, fiber laser engravers generate a wide range of grays (from white to black) on the surface of aluminum. They are used to:

- Permanently mark QR codes, data matrix codes, serial numbers, and logos.

- Engrave various aluminum parts such as castings, ingots, sows, slabs, billets, sheets, and extrusions.

- Etch all types of aluminum, including anodized aluminum and common alloys (Aluminum 380 and 6061).