eBook

How Barcodes Work

Everything You Need To Know About Industrial Traceability

Traceability is essential to protect businesses from the negative consequences of product recalls and counterfeiting. High-quality barcodes are at the heart of a good traceability system.

This guide will help you understand how to use barcodes for traceability. You will also find related tips for production lines.

Features

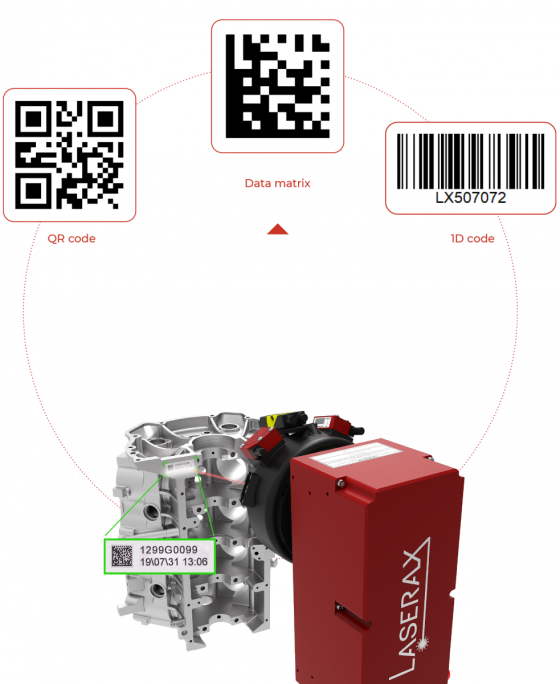

- Types of barcodes (1D codes, QR codes, data matrix codes)

- How barcodes work (code size, physical size, error correction, quiet zone, contrast, shape)

- The importance of databases (control over the information, smaller codes, more information)

- Storage capacity table for data matrix codes

Sign up and get our free ebook

Other Ebooks

Choose Your Next Laser Marking Machine in a Simple Way

Choose Your Next Laser Marking Machine in a Simple Way