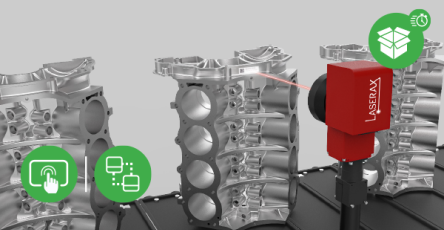

Laser System Options

Laser Power

The LXQ-LP is available with 10W or 20W of output power.

For high-speed applications, 30W to 100W fiber lasers are available as part of the LXQ Series, and 200W to 500W fiber lasers as part of the LXQ-HP series.

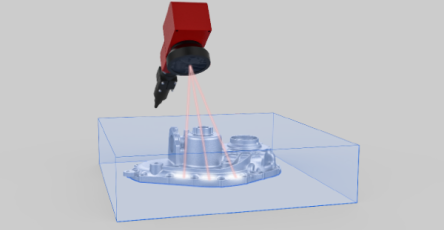

Lens Configuration

Our standard lens provides the best optical configuration for most part marking requirements. The marking field is large, and the marking distance is long enough to reduce dust accumulation on the lens.

Our advanced lens is used to obtain a laser engraver. This configuration helps the laser create deep engravings into the material to create more durable markings. It can also be used or to texture surfaces.

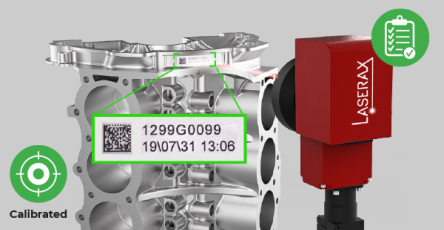

Barcode Validation

If you have part traceability needs, our barcode validation system and Cognex camera validate marking quality as soon as 2D codes are marked. The camera is delivered preconfigured and only needs to be connected to the controller’s back panel.

Air-Knife

Installed on the lens to protect it, the air-knife blows a continuous airstream that prevents dust accumulation. This guarantees consistent high-quality results and greatly reduces lens cleaning maintenance.

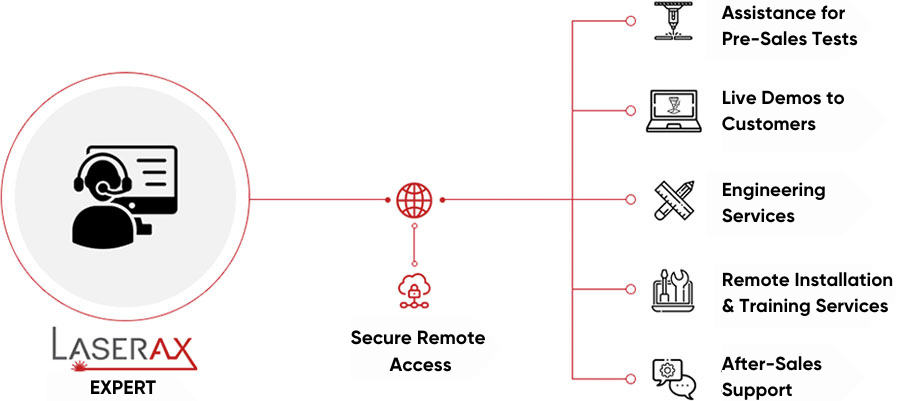

For our complete list of features and options, contact a Laserax expert.