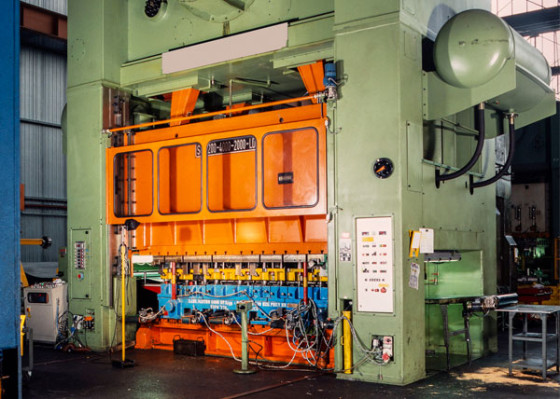

Laser Marking In Stamping Production Lines

Hundreds of stamped parts with the same batch number can lead to expensive recalls and hard-to-trace quality issues. To ramp up traceability capabilities, laser marking can be used to generate a unique identifier for each part.

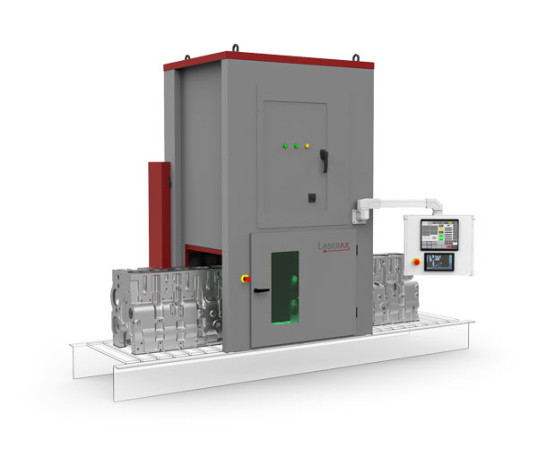

Laserax’ unique technology allows you to create 2D codes that survive stamping and e-coating, making it possible to integrate traceability before these processes.

Our fiber lasers can mark around 60 parts/minute, providing the speed you need to keep up with the stamping press production volume.