Door Laser Cleaning Machine

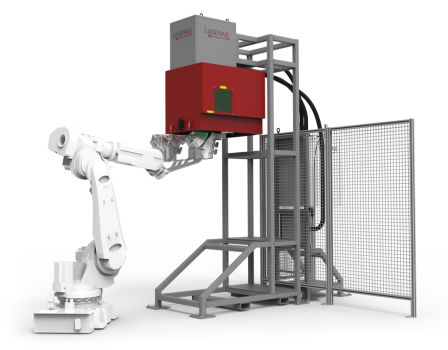

Easy to integrate in robotic cells, the door machine is extremely compact. You get to optimize your plant layout with maximum flexibility, as the robot can load parts from any direction.

Read more

Easy to integrate in robotic cells, the door machine is extremely compact. You get to optimize your plant layout with maximum flexibility, as the robot can load parts from any direction.

Read more

The Automated Conveyor Machine is an inline laser cleaning machine designed to rapidly remove contaminants from parts as they move on a conveyor (on-the-fly technology) or while a conveyor is stopped.

Read more

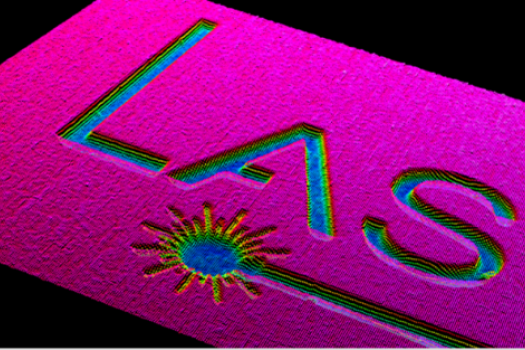

This technical paper reports the deep engraving speeds and surface finishes obtained during tests performed by Laserax using the LXQ-HP laser system. Measurements were taken for typical engraving depths on steel and aluminum, and this, at different power levels

Read more

Equipped with a semi-automated rotary table, the Rotary Laser Marking Workstation provides the highest throughput of all manually loaded laser marking machines, making it ideal when the available cycle time is limited.

Read more

The Rotary Table Laser Marking Machine is a fully automated inline solution designed to optimize your marking cycle time.

Read more

The Open Air is an inline laser marker designed to provide direct part marking within your robot-assisted manufacturing process without using any costly part fixtures.

Read more

Fully customizable in shape and with lots of options, the Automated Door Laser Marking Machine is our most flexible solution.

Read more

The Automated Conveyor is an inline laser marking machine designed to apply permanent and high-definition labels on parts and ingots.

Read more

Laserax's LXQ fiber lasers are a perfect fit for applications that involve metals such as aluminum, lead, tin, magnesium, nickel, steel and stainless steel. Its huge field of work and focal depth are favored by industrial buyers.

Read more

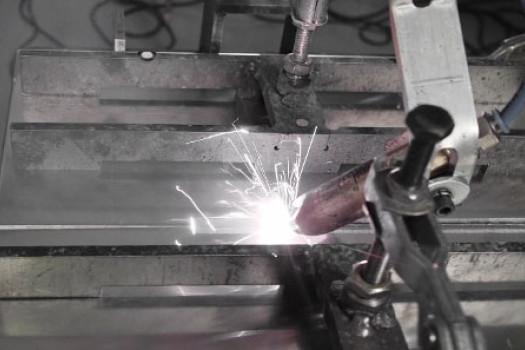

This technical paper reviews the benefits of implementing laser cleaning before and after welding applications. It also provides cleaning speeds for the Laserax LXQ-HP laser systems to show that laser cleaning can be integrated in production lines without affecting the production output.

Read more