De-Risking Battery Welding Scale-Up and Replacing Wire Bonding

During their development phase, Scania sought out a laser welding solution to replace their traditional cell joining process (wire bonding). A solution that combined precision, versatility, and speed with advanced dynamic clamping capabilities to meet all their requirements. That's where Laserax came in.

Objectives

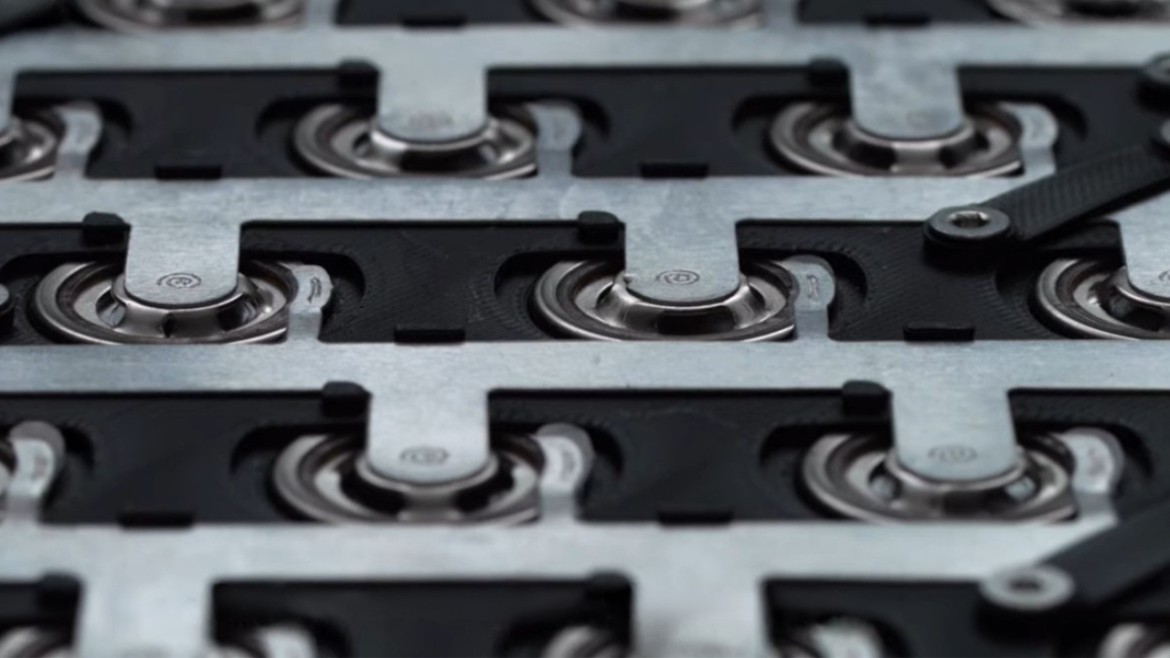

The main objective was to replace ultrasonic wire bonding end-to-end with an industrial laser welding process for cylindrical cell modules (21700 format).

Industrial laser welding is not only 5 to 10 times faster than ultrasonic wire bonding, but it also halves the number of welds required for each cell (from 4 to 2). This advantage compelled Scania to adopt laser technology since each module required two welding types:

- Current collector plates to cell terminals (154 cells, 308 welds)

- Current collector plates to terminal busbar (2 welds)

- Total: 310 welds per module

In order to achieve high yield with a complete welding solution, Scania needed strong technical expertise to meet a takt time of ≤ 39s per module and precise validation specs (shear test, electric resistance, weld penetration/geometry, maximum internal cell temperature, weld duration). The client also required embedded flexibility for three different welding patterns: circular, sinusoidal, and linear.

The laser solution thus needed a high-precision and low-margin laser process that includes:

- Engineered clamping

- Integrated vision

- Automated weld quality control

For our project to weld 21700 cylindrical cell modules, we were seeking a fast and flexible laser welding machine to accommodate our needs for high throughput and the continuous evolution of our product design. Laserax’s technology seemed to be the perfect fit for our needs, offering speed and flexibility through its robotic dynamic clamping while maintaining high welding quality.

The company supported us from the early development of the welding process all the way to product design adaptation. Now that the machine has been delivered and is performing very well, we are glad we trusted Laserax. They were not only a supplier but also a trustworthy partner for Scania, and they tremendously helped our company achieve its goals. – Karl Fahlström, Manager Technology Development, Scania

Solution

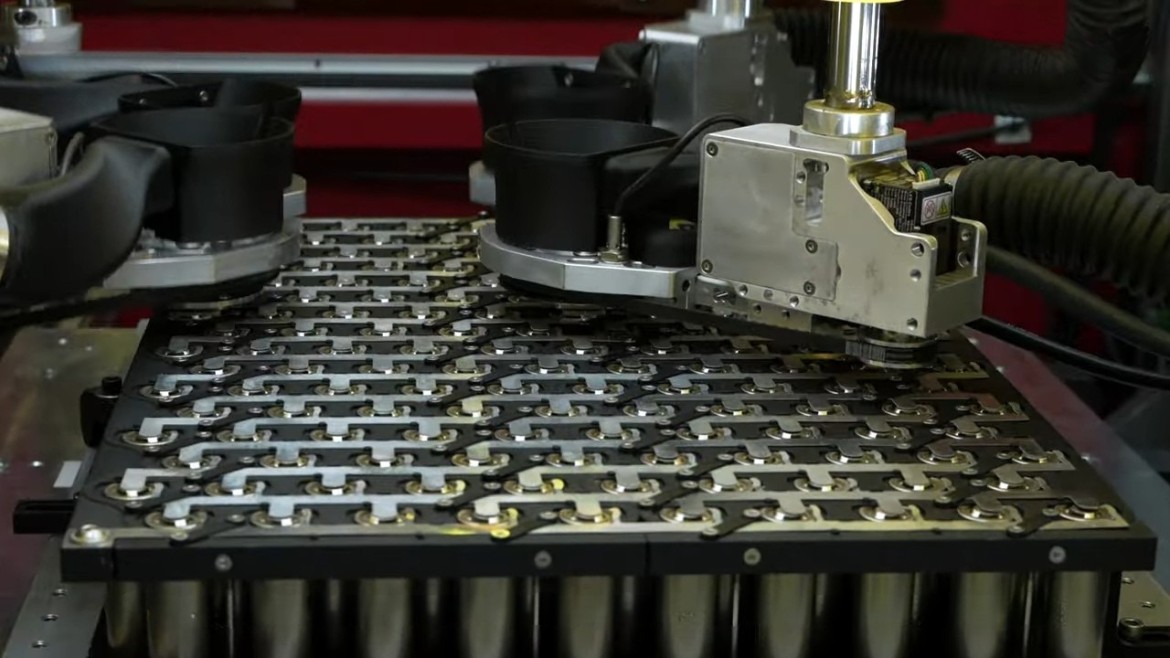

Laserax supported Scania from the initial laser process development by adapting the design for full-scale production and delivered a custom-made Battery Laser Welding Machine.

The solution was configured at 1kW with four SCARA robot heads, dynamic clamping paired with inline 3D stereoscopic vision & real-time quality monitoring (LWM), and a Class-1 safety enclosure with fire and heat detection (as requested by the client), all orchestrated through a unified control software.

Together, we got to work developing a laser welding machine designed not only to meet their technical requirements but to make the entire process smoother, while improving quality, reliability, and scalability.

Output

Scania now has a turnkey machine they can count on. A solution that reduces the risk of scaling production while delivering the performance and speed they demand.

In fact, Laserax’s solution not only meets the client’s thresholds for shear strength, contact resistance, penetration/geometry and per-cell weld duration, but also exceeds the client’s takt target (39s) by delivering the requested 310 welds per module in 37s.

Benefits of Our Solution

- Versatile and Scalable

Adaptable to various packs and cell formats - Manual or Automated Conveyor Loading

From prototypes to full production capacities - Fastest Welding Process in the Industry

<100 ms per cell - Welding and Dynamic Clamping Adapted to Cell

Pressure and position feedback (±100 µm) - Multiple Robots to Maximize Laser Uptime

4 SCARA robot heads

Manufacturing Improvements

- Larger current-carrying interface

- Half as many potential failure points

- Improved current distribution

- Higher current per weld

- Reduced I²R loss and heat generation

- Better heat transfer from cells to busbar conductors

- Less mechanical stress is transferred to the module