Laser Machine Options

Laser Configuration

With up to 500W of available laser power, our experts can adjust the marking speed as needed to fit your cycle time.

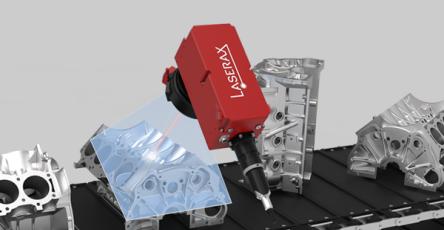

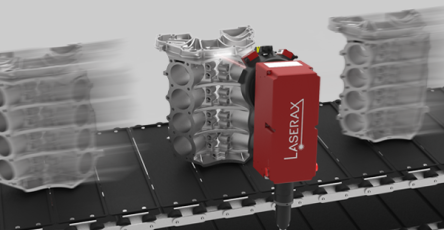

Autofocus System

Since parts are rarely precisely positioned on conveyors, the 3D Autofocus system detects part positioning variations and uses that information to automatically adjust the marking process. This allows you to consistently generate high-contrast markings.

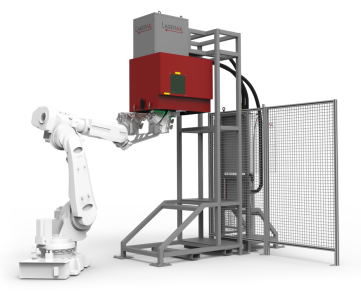

Gantry System

The fiber laser marker can be mounted on a gantry system to operate within a larger marking area and etch multiple marks on the same part.

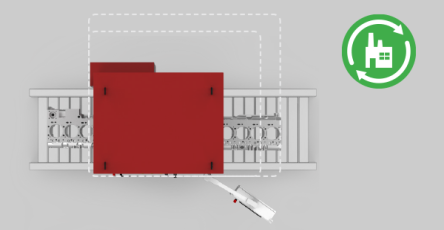

X-Y Vision System

The vision system locates parts that are beyond the laser marker’s field of view when part positioning variations are too high on the conveyor. The laser head is then moved to the right location to perform laser marking.

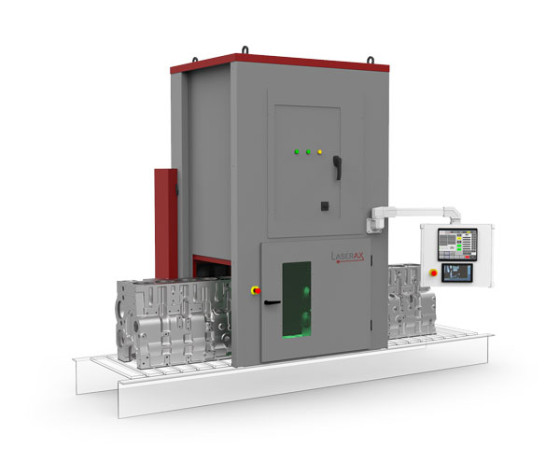

HMI Control Panel

The standard HMI control panel provides direct access to laser marking parameters near the machine. You can:

- Manually adjust the laser marking zone, scale the identifiers, edit them and more

- Enter the manual operation mode to run tests or calibrate the laser

- Display information such as the system status, the operation mode and the alarm history

If you want to add custom features in the HMI, contact us.

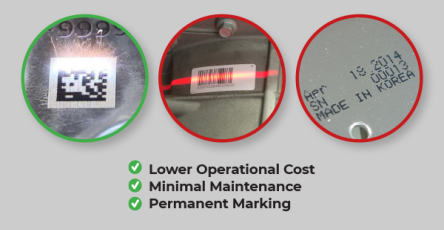

Barcode Validation

Marking quality can be verified directly in the machine with our standard barcode validation system and precalibrated Cognex camera.

For more machine options, contact a Laserax expert.